The limitless potential of sound-absorbing wall coverings

Written by

22 March 2022

•

5 min read

Discerning the difference between good and not-so-good interior spaces comes down to a swathe of factors — the quality of architectural design, whether it’s functional, – and a host of others.

In a broader sense, though, it comes down to the ‘feel’ of the space — and this is determined by our sensory inputs. This is obviously dominated by the sense of sight: how a space looks forms the primary basis for our perception of it. But beyond this, the other senses are routinely overlooked — particularly, the sense of sound.

Building products that improve acoustics are important for most commercial and residential spaces, but rarely do they also function as an aesthetic feature — a true blend of visual form and aural function.

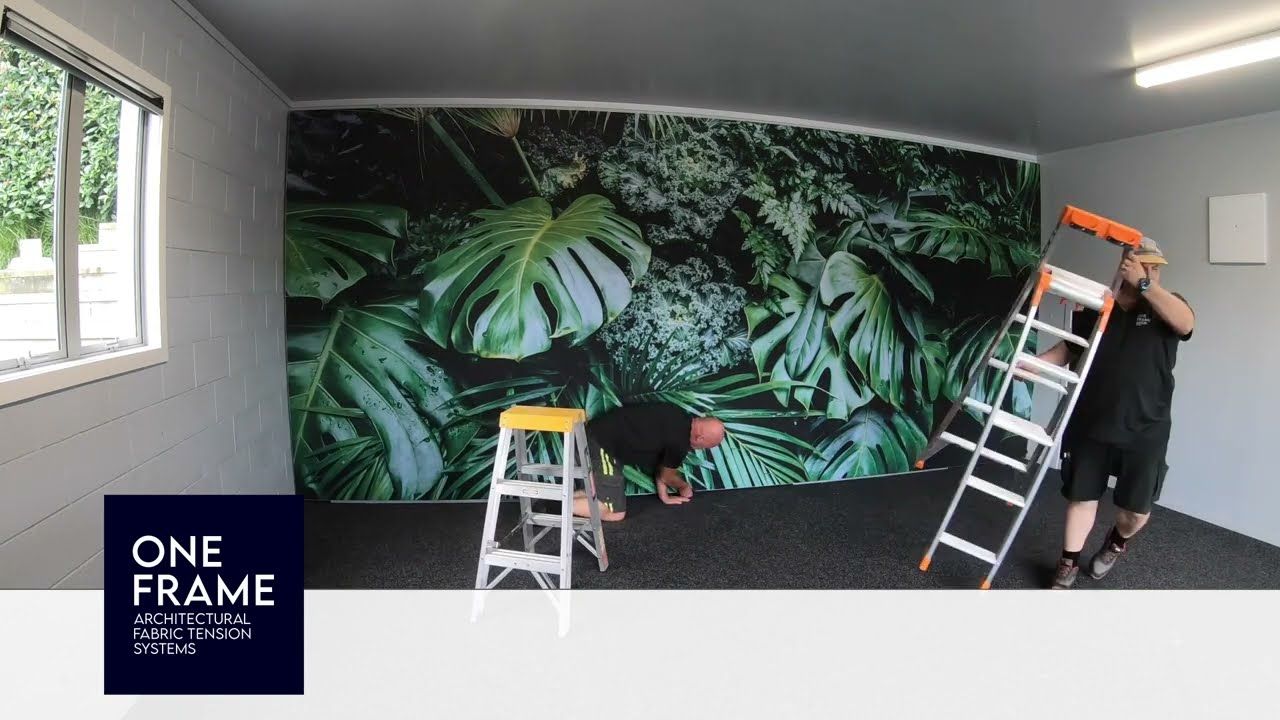

OneFrame’s resonate sound-absorbing stretched fabric system is one such product, made in New Zealand and designed to deliver both an aesthetically pleasing visual paired with a functional acoustic treatment within any environment. The resonate offering allows for the custom printing of any colour, pattern or image onto purpose-made acoustic Clipso fabric, shaped to fit any wall or ceiling.

OneFrame director of client services Jacques Swanepoel says the product was borne from a particular customer demand that the company was well-placed to deliver: an acoustic wall solution with the flexibility to display design, image or branding.

“We began to get enquiries to develop a whole range of custom executions where traditional acoustic solutions fell short,” says Jacques. “Customers wanted options where they could fully brand wall coverings, with no seams, and with the ability to be updated with minimal disruption.”

resonate: a multi-functional solution

The system relies on a sophisticated frame system, customisable for each space’s shape, span or size, which is fixed against the wall. The acoustic panel is then fitted within the frame, after which the printed fabric is perfectly tensioned into the frame.

The acoustic performance of the product is evident: Jacques says resonate has been installed in several hearing clinics across the country, where audiology testing spaces require specific aural specifications in order to function properly. In this application all testing and specifications of the acoustic requirements was done by the client prior as it needed to fit some strict criteria.

The fabric wall systems in these scenarios tend to have decorative or lifestyle imagery printed onto the fabric — all designed and supplied by the client to fit their unique interior styling and brand.

“We’ve also done some hotel corridors, which had art running across the hallways while also providing acoustic performance for the guests,” says Jacques. “It’s very much an acoustic product, but with the added benefit of customising to any size, any scale, any print that you want.”

It’s not just commercial spaces that can benefit from OneFrame’s resonate product: Jacques says the company is fielding many enquiries from residential homeowners too, looking for an alternative to wall coverings that are firmly in the status quo.

“Usually it’s someone that usually would have gone for a traditional wallpaper to create a feature wall, but then they opt for this because it fulfils the same purpose while also providing the acoustic delivery on top of that,” he says. “They find a lot of value in the two-in-one function.”

No seams, no compromises

Perhaps the key product differentiator setting OneFrame’s resonate apart from its competitors is its ability to install very long fabrics with absolutely no seams.

“A traditional acoustic panel is generally 2400 x 1200mm,” says Jacques. “This means it’s hard to avoid seam lines when covering larger walls.”

OneFrame’s product, however, can stretch to 50 metres long and 3 metres tall without a single seam. This is possible because of the company’s printing technology and capabilities.

“Other companies print directly onto the substrate, which can often mean the resolution is not that great and it’s prone to scratching, scuffing and marking,” says Jacques. “Whereas our printing is done through dye sublimation.”

This process involves putting the required ink onto paper. The paper then runs through a heat process that turns the ink into a gas form — which then thermally bonds to the polyester fibres within the fabric.

“So that means you can take this piece of fabric and scrunch it up, and the print won't crack,” he says. “You can scuff it, you can wash it, it’s very durable.”

Thus, Jacques says, from a longevity and colour vibrancy perspective, there’s no comparison to anything else on the market.

Any damage or update of traditional solutions are rather evasive and costly with the entire solution needing to be removed and replaced. In contrast, the OneFrame’s resonate system largely stays in place, and it is only the printed skin that needs to be updated or replaced if required.

Best of all, this is usually done with minimal disruption, and in so doing lends itself to more frequent updates as the internal environment changes.

The product can be summed up in a simple word that emcompasses its many qualities and benefits: seamless.

Learn more about OneFrame’s products and solutions.