EXPOL Geofoam

EXPOL GeoFoam (EPS – Expanded Polystyrene) block is used as lightweight fill in problematic situations.

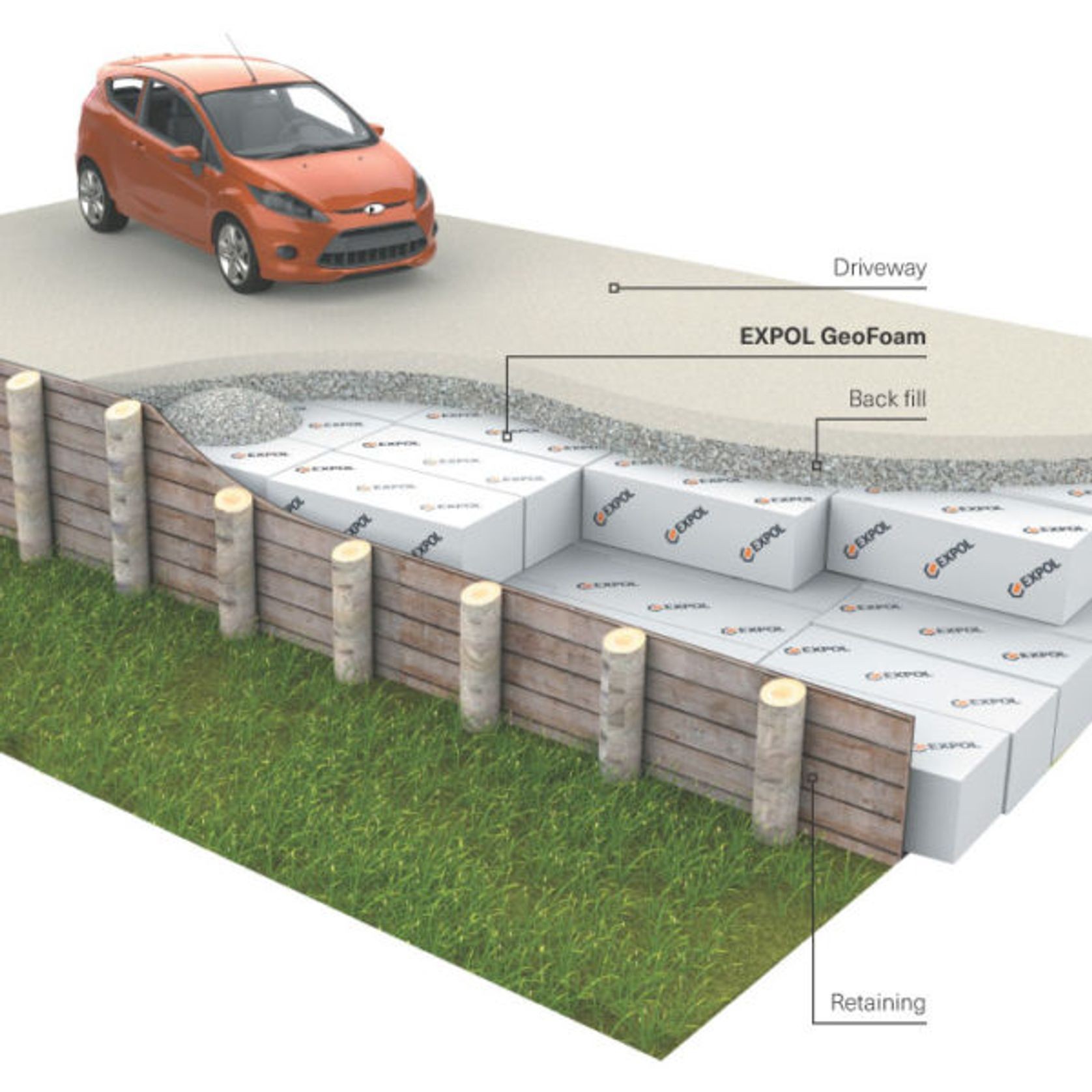

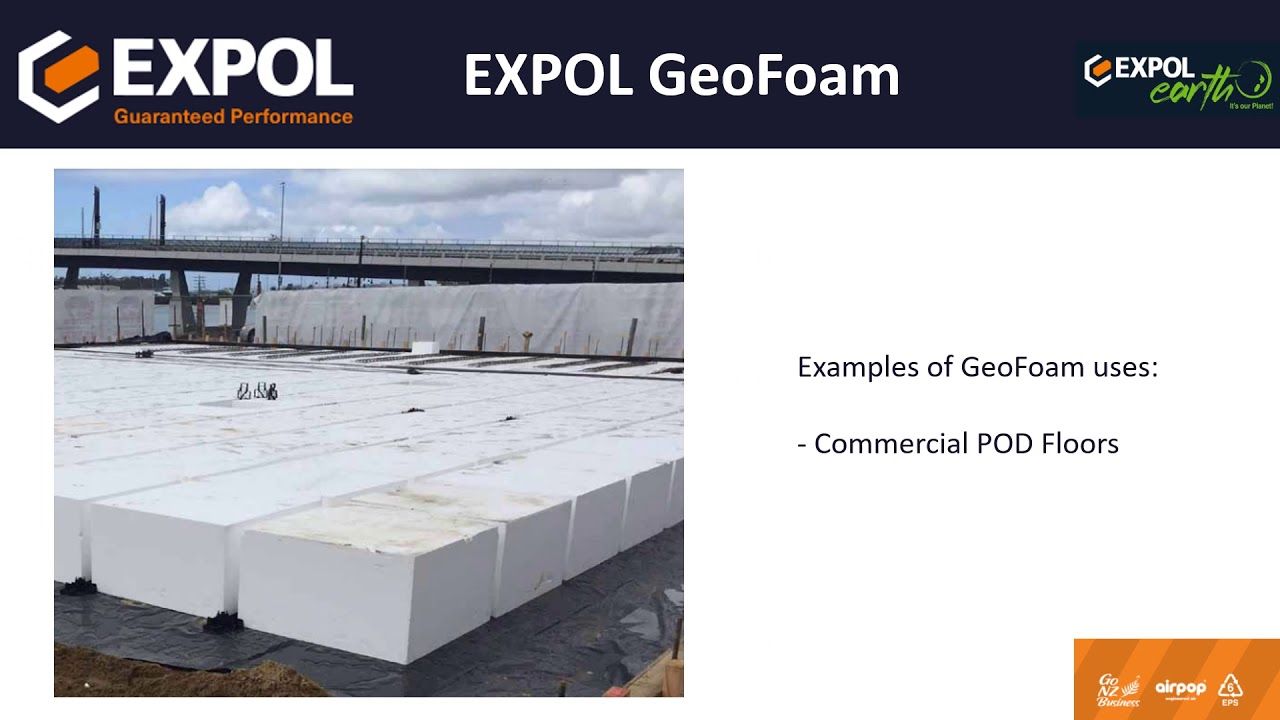

It is multi-functional and is suitable for a wide range of applications, including construction on soft ground, slope stabilization, and civil infrastructure work such as bridge abutments, airfield pavements, and railway track systems.

EXPOL GeoFoam (EPS – Expanded Polystyrene) is preferred by specifiers and engineers because it reduces construction costs and timeframes, is easy to handle, can be cut on-site, and is unaffected by weather conditions.

It offers exceptionally high compressive strength despite weighing only 1% of traditional soil fill and 10% of conventional lightweight fills.

It is made from (EPS – Expanded Polystyrene) beads that have been moulded into blocks, Lightweight fill can be cut into any size or shape depending on the requirement of the project.

As an ultra-lightweight fill, the stress on underlying subgrades and adjacent structures is significantly reduced. It helps improve stability against bearing and slope failures.

- CategoryStructural Flooring

- RangeEXPOL Geofoam

- BrandEXPOL

- Country of originNew Zealand

- Type of useCommercial and Residential

- Care and cleaningEasy maintenance

Expol GeoFoam Advantages

- Lightweight

- High compressive strength

- Cost effective

- Durable

- Weighs 1% of conventional fill

- Eliminates lateral pressure and vertical movement

- All clean waste can be recovered for recycling

Applications

- Construction

- Road embankments

- Bridge abutments

- Causeways

- Retaining wall fill

- Replacement of poor soils

- Landscaping

- Geotechnical fill

- Frost heave protection

- Sites with limited access

EXPOL GeoFoam (EPS – Expanded Polystyrene) clean waste can be recovered for recycling.

It is ideally suited for use in construction over soft substrates, road embankments, bridge abutments, causeways, retaining wall fill, and for replacement of poor soils, landscaping, geotechnical fill, frost heave protection, and on sites with limited access.

GeoFoam is manufactured from standard Expanded Polystyrene foam and is available in a variety of grades to suit different construction conditions (see Table 10.2). Typical densities range from 12kg/m3 to 32kg/m3. GeoFoam will absorb small volumes of water, however, this will not have a significant effect on its mechanical properties or performance.

All products and grades of Expanded Polystyrene supplied by EXPOL for lightweight fill comply with manufacturing standard AS 1366 Part 3 1992.

EXPOL can provide a producer statement for all EXPOL GeoFoam material on request.

About the

Seller

Trusted by Kiwis for more than 40 years, EXPOL responsibly manufacture and distribute New Zealand’s largest range of solid insulation and lightweight polystyrene construction solutions.

Ever since founder Terry Mischefski cut the first block of polystyrene in the 1970s, innovation and flexibility have been at the core of EXPOL’s operations.

Today EXPOL is committed to the environment and takes responsible manufacturing seriously.

- ArchiPro Member since2023

- LocationView all locations (+6)

- More information