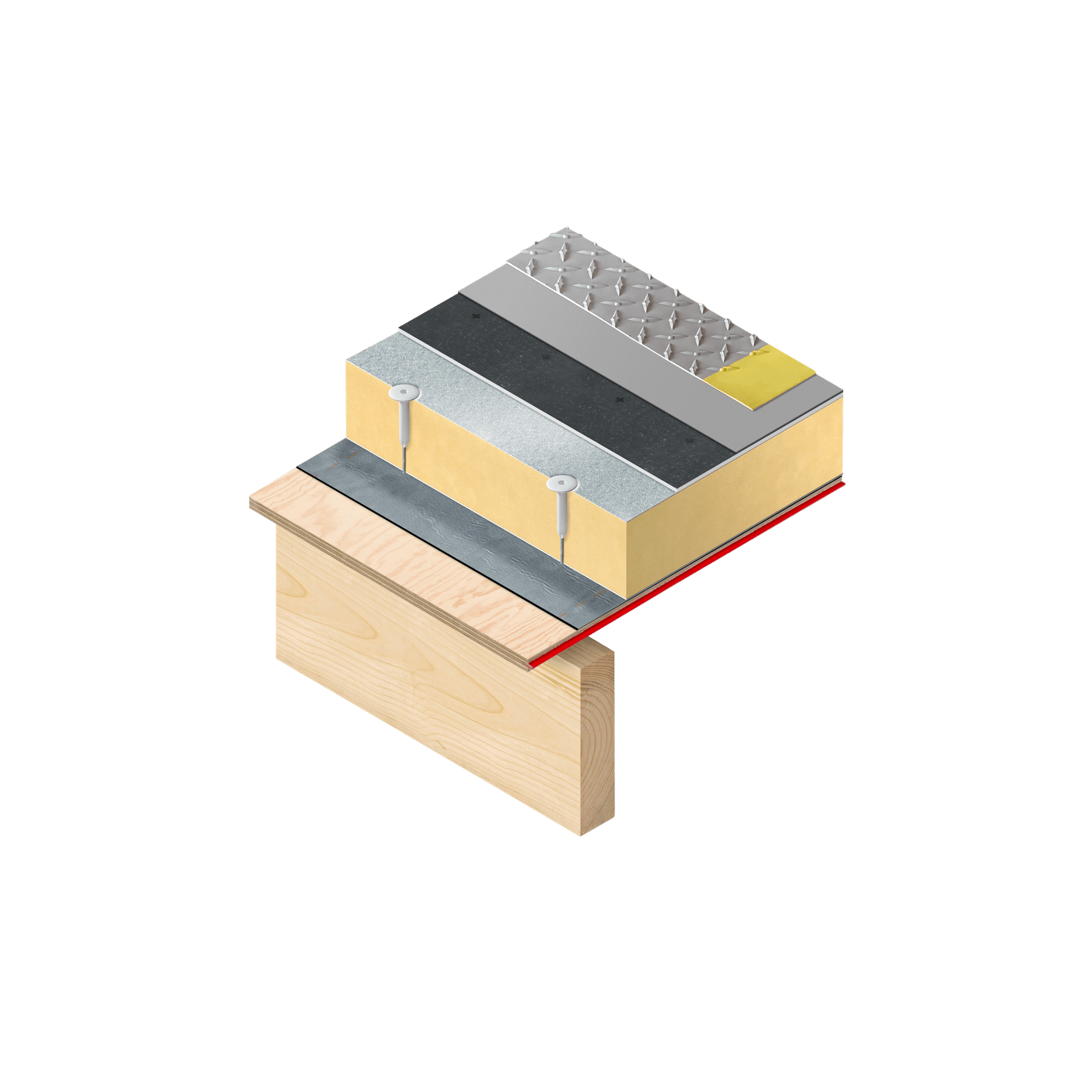

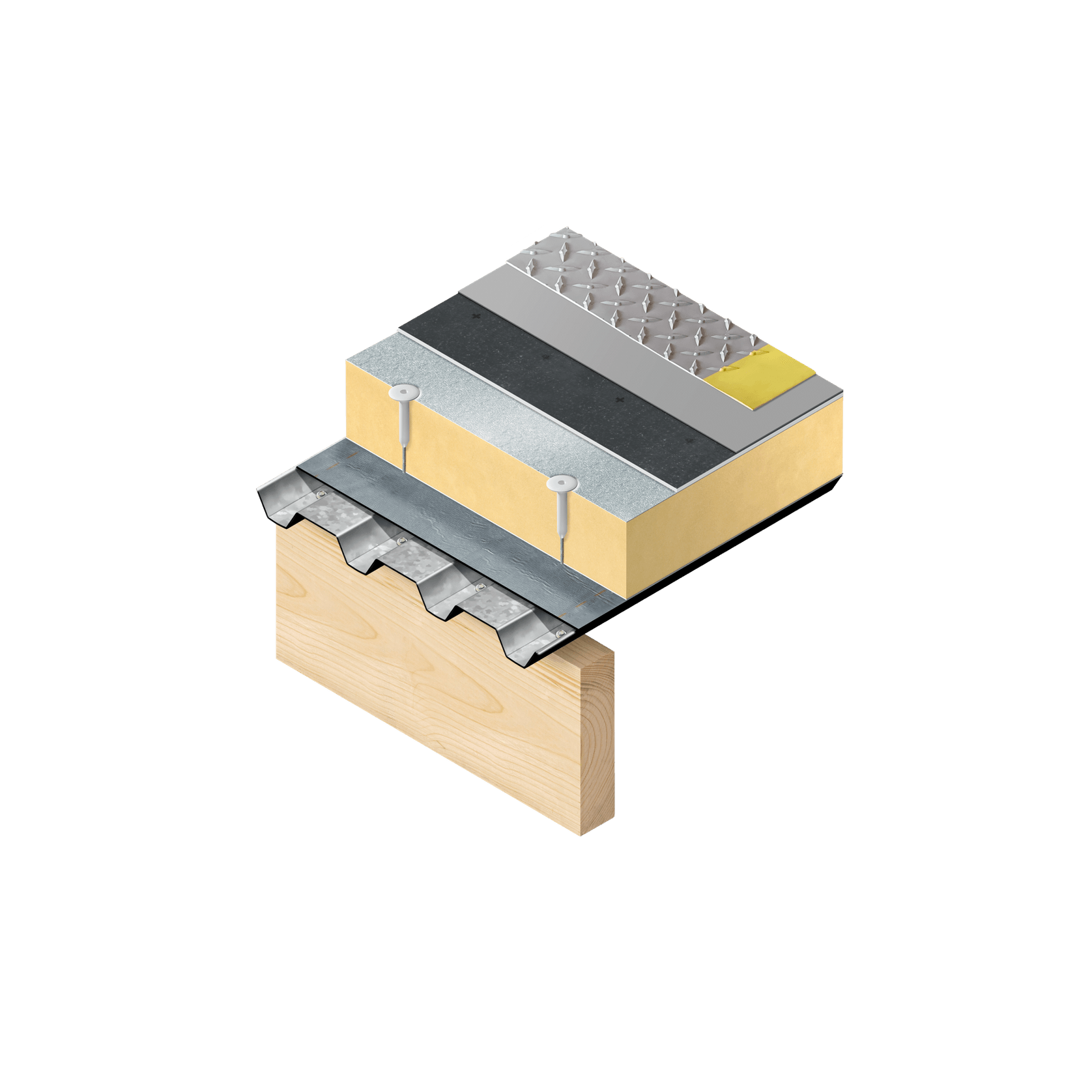

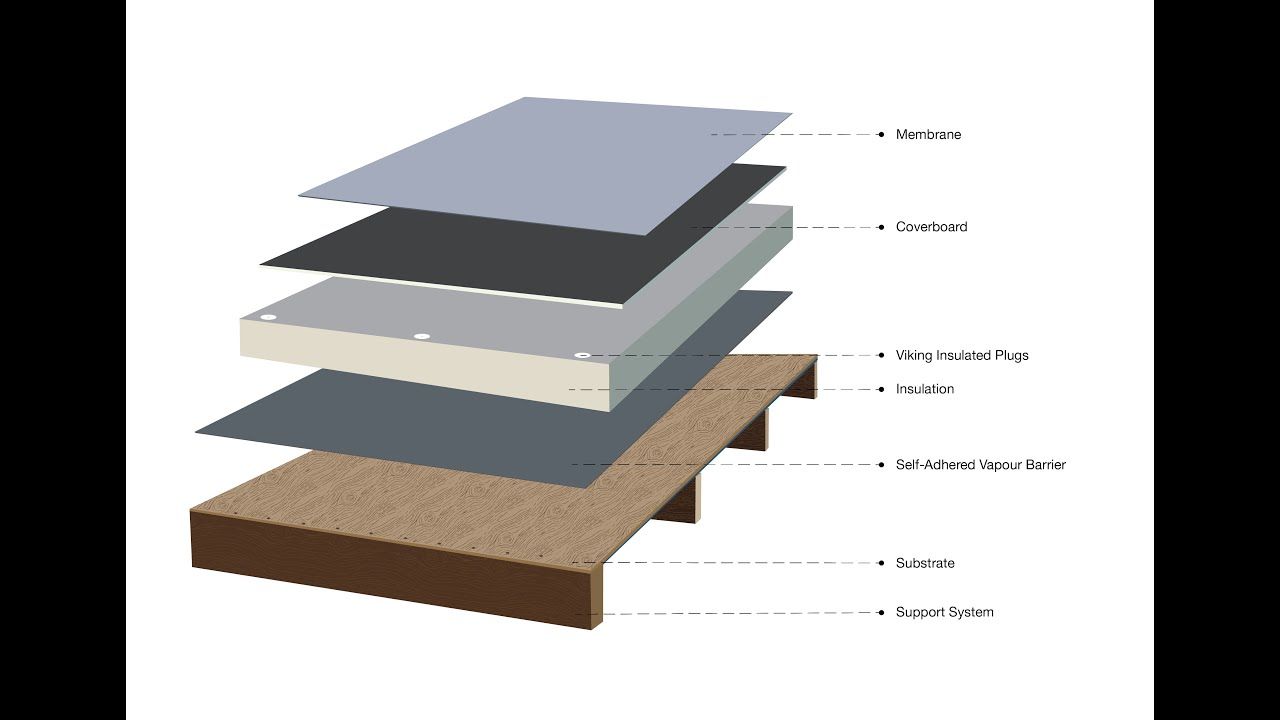

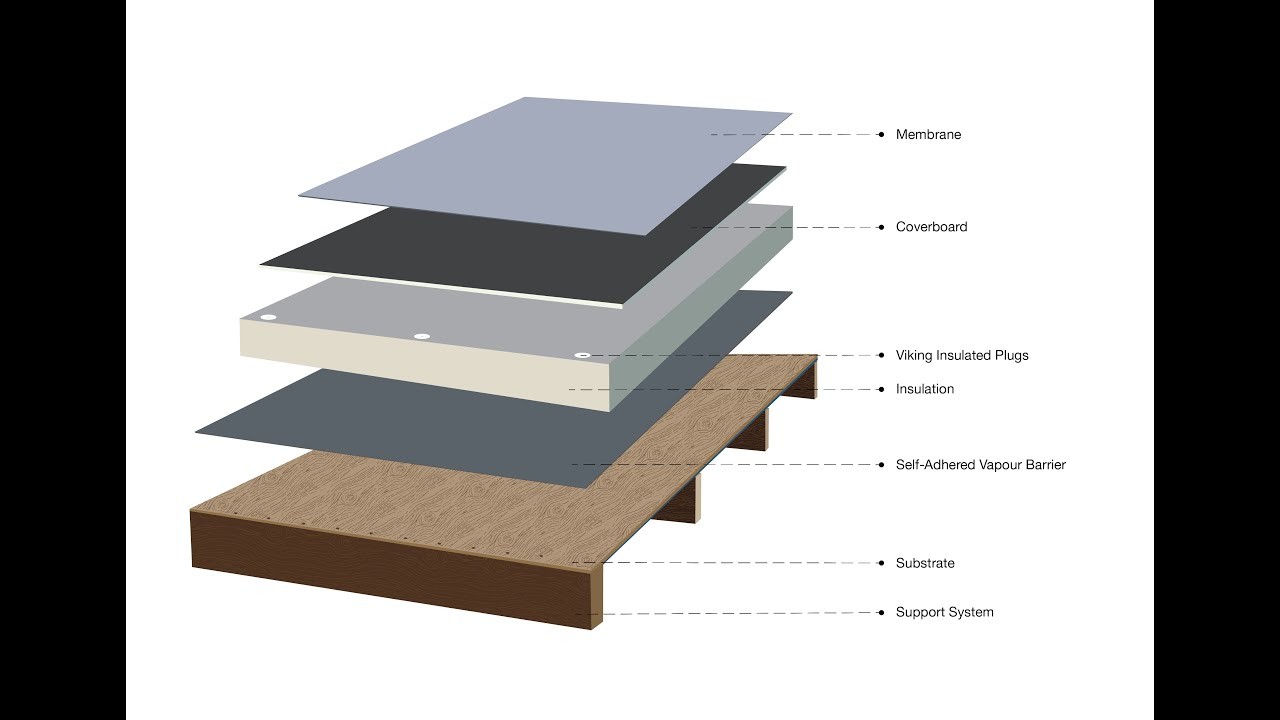

Viking WarmSpan²

Viking Roofspec- CategoryWarm Roofs

- RangeMembrane Roofing

- Warranty20 years

More from Viking Roofspec

About the

Seller

Viking Roofspec is a market leading provider of quality waterproofing and roofing materials and is proud to be 100% owned and operated.

Keeping water on the outside.

Whether it's a home or commercial building, Viking's Roofing, Decking and below-ground waterproofing systems, keep water out and ensure it stays out... for good.

Viking Roofspec is a market-leading provider of quality roofing and waterproofing materials. We've been protecting properties in New Zealand, the Pacific Islands and even Antarctica for nearly 50 years.

We work closely with all key stakeholders during the development of a building or home. From design through to specification and installation, we provide advice and support where required. We take a full system approach to waterproofing to ensure a watertight, professional finish is achieved.

To speak to your local representative, click here.

Our applicators are nationwide. Click here to find one closest to you.

- ArchiPro Member since2016

- LocationView all locations (+2)

- More information