A maker’s touch gives Harbro its distinctive soul

Written by

30 November 2025

•

4 min read

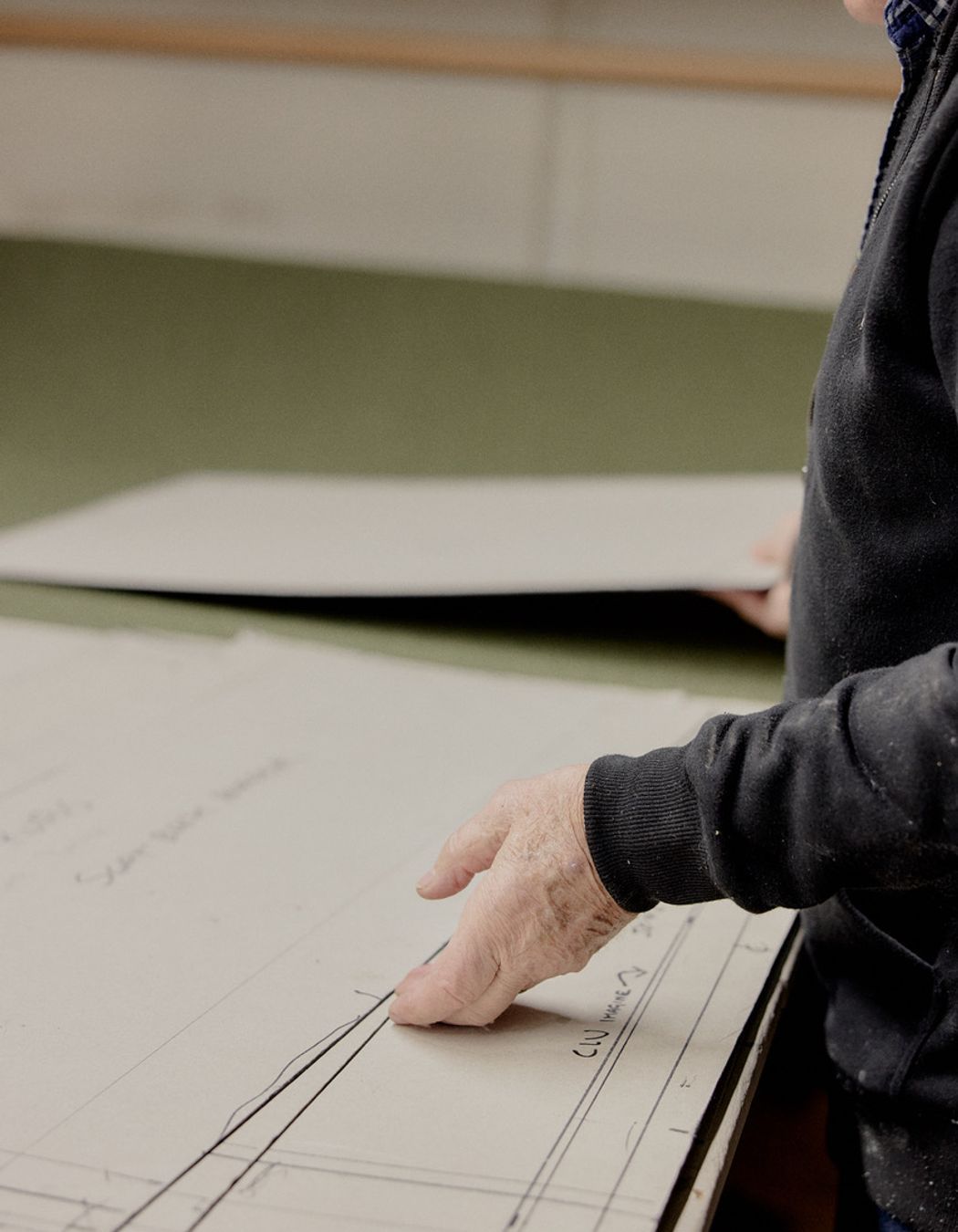

Tucked between a cleaning product supplier and aluminium distributor, Harbro Furniture’s workshop is easy to miss, but step inside and you’ll find the kind of energy that only comes from people who genuinely love what they do.

For more than three decades, this small factory has been crafting furniture the traditional way: by hand, with patience, precision and pride. There’s no major machinery or mass production line, just makers putting the skills they’ve spent years refining into practice. There’s music playing and tools buzzing. A rhythm only interrupted by a 10am team coffee run before the routine starts all over again.

“The atmosphere is great, people genuinely enjoy what they do here,” shares Bryce Hardy. “Every Monday morning we have a meeting to talk about the weekend, the week ahead, and any project details.”

In a well-rehearsed form, each team member has a designated station to keep the workflow consistent. “Roula runs our supply chain and operations, my father Brian, Mark, and Kirk do most of the manufacturing and upholstery, and Michelle handles cutting and sewing. Sometimes my sister comes in to help with prepping - it’s really a family effort.”

It’s been this way for decades. The only difference is a few more pairs of hands at work.

When Bryce officially joined the family business around 16 years ago, it was him, his father, and one upholsterer. “We did whatever was needed to get the job done. What I love now is that we’ve got the right people in the right places, which makes the whole place flow.”

Aside from a few refinements, the process hasn’t changed much. “We still make everything by hand using traditional craftsmanship.”

When a custom project comes in, everyone’s focus shifts. “Because we’re such a small team, custom work really changes the pace,” Bryce explains. “A one-off piece might take two or three people away from production, and suddenly the whole output slows. But that’s the trade-off. Those pieces are really special.”

If there’s one thing that has evolved over the years, it’s the focus on quality materials and taking the time to craft more bespoke pieces. The focus has shifted from volume to refinement, and only the best fabrics are selected. If anything feels too mainstream, it doesn’t make the cut.

The philosophy is simple: do more with less. “These days we create more modern, contemporary pieces,” says Bryce. “Compared to when we started, we’ve pared back our style, simplified the design and construction, and focused on using the best materials and our team’s expertise to achieve the results we do. We rely heavily on the skill of our craftspeople.”

With today’s adoption of technology, there’s a growing fascination with things that remain true to their original form. Pieces that are the result of someone’s time, care and touch. And that’s exactly what Harbro delivers.

“We’ve really made a conscious decision to do whatever it takes to be the absolute best we can, to create the best possible furniture every time. It’s easy to cut corners, to choose cheaper materials to save on cost and rush the upholstery, but we don’t accept ‘good enough’. If something’s wrong, we know it’s wrong and we fix it. It simply has to be right. We’re a simple, hands-on workshop. It’s about doing our best work with what we have, not overcomplicating things,” says Bryce.

“We’re not a big business that’s filled with machinery and no heart or soul. We’re a small team that really does our best. We enjoy what we do, and we’re here because we enjoy it.”

Bryce and the team love sharing their creations at their Richmond showroom. Pop in for a visit or get in touch with Bryce to start the creative process.

We’re not a big business that’s filled with machinery and no heart or soul.