A super customisable cabinet door range in a paint-ready finish

Written by

23 July 2023

•

4 min read

The success of an interior space is often dependent on the small design moves made at the very outset of the project; proportions and design details need to align perfectly to please the eye.

In kitchens, particularly, linear details and the proportions of cabinetry needs to be carefully considered so there aren’t odd, thin or thick bits jarring the visual continuity of the space. This can be difficult to achieve with standard sized cabinet door ranges, because the one-size-fits-all approach often creates odd-looking lines or strange proportions on the edges of a door.

Sage Doors have addressed this issue with their highly bespoke range of Optidoor cabinet doors.

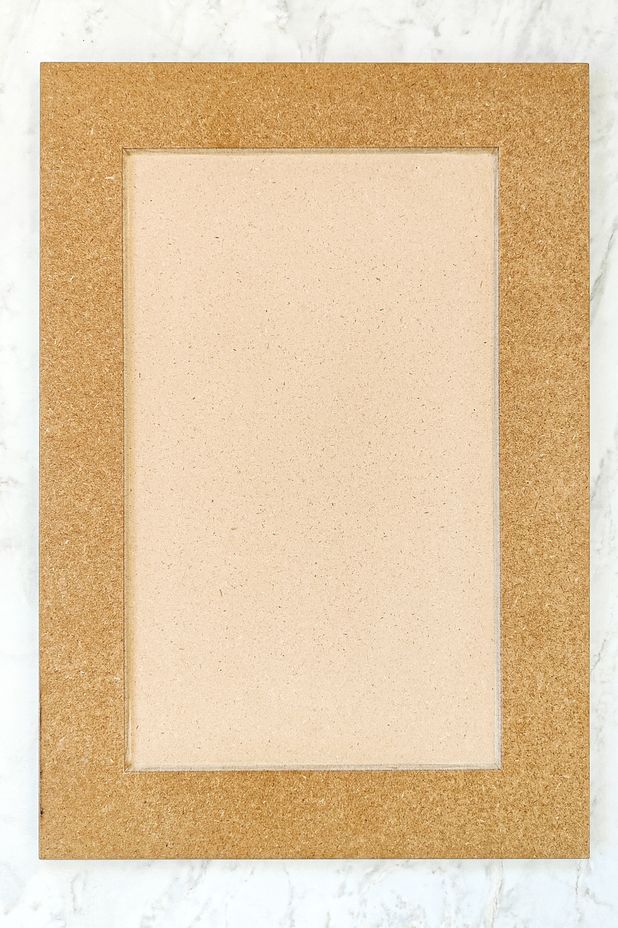

“We use the words ‘customisable’ and ‘variable’ to describe the Optidoor range,” says Sage Doors Operations Manager Lydia Posthuma. “The customisable part is the aspects that you can change, for example, changing the size of the frame and setting the size of all the dimensions within the design of a linear profile door, whether it’s a frame or lineal routed design. The variable part is when we automatically adjust those proportions and lines to fit the design of the kitchen or space so that the profile looks consistent across the design, with no flat bits on the edge of your door.”

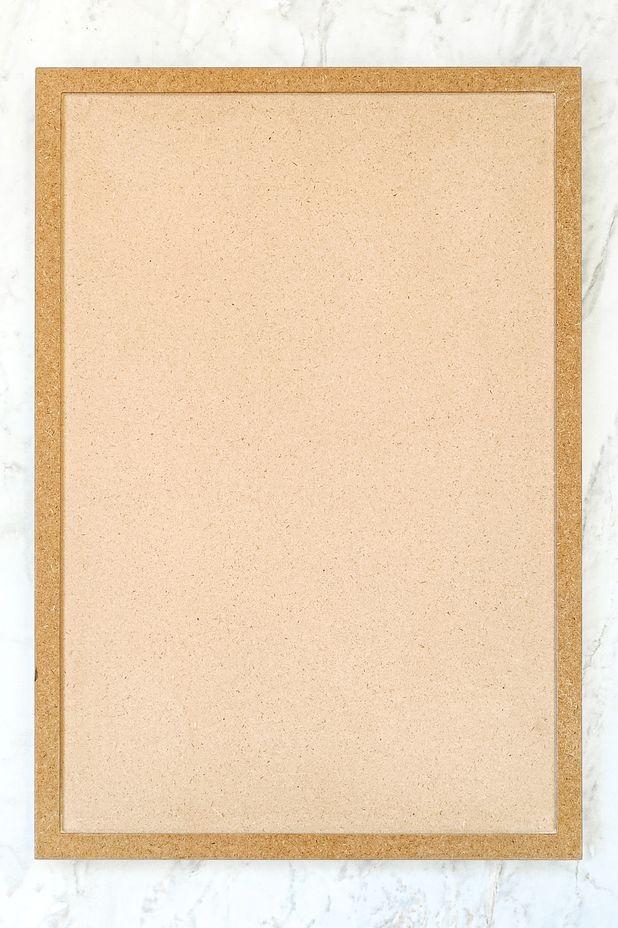

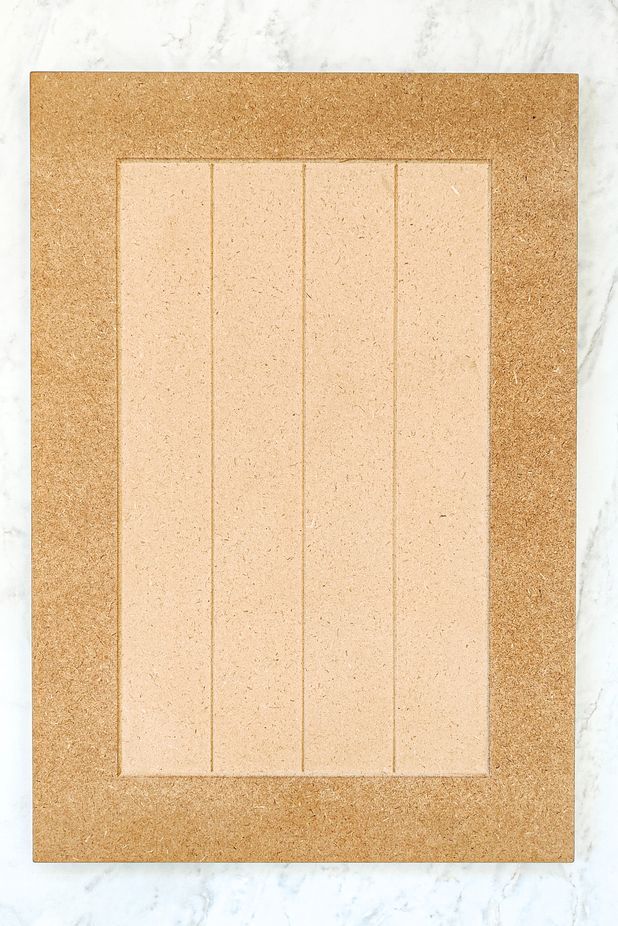

The flexibility of this approach makes specifying a customised and high-end look incredibly easy. Added to this, Sage Doors offers a wide range of styles including: Shaker-style framed doors; narrow-framed traditional doors with a fine bead; mid-century modern-style doors with a rounded, channel detail; and a number of lineal, routed styles; as well as the traditional V-groove.

“People can choose a style but they also have the option of customising that style, like adding extra length at the bottom of a round channel-style door to create that radiator kind of look.”

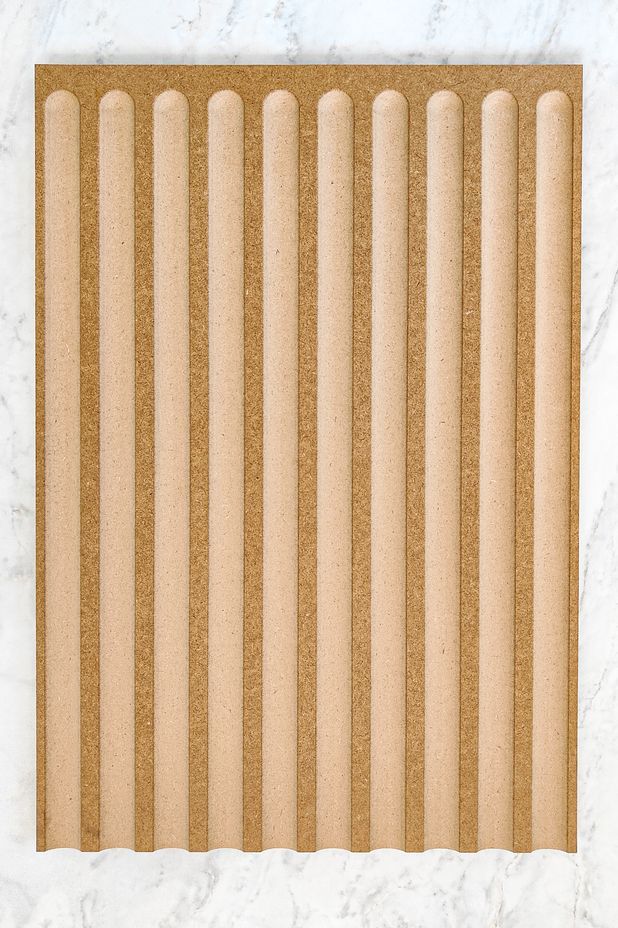

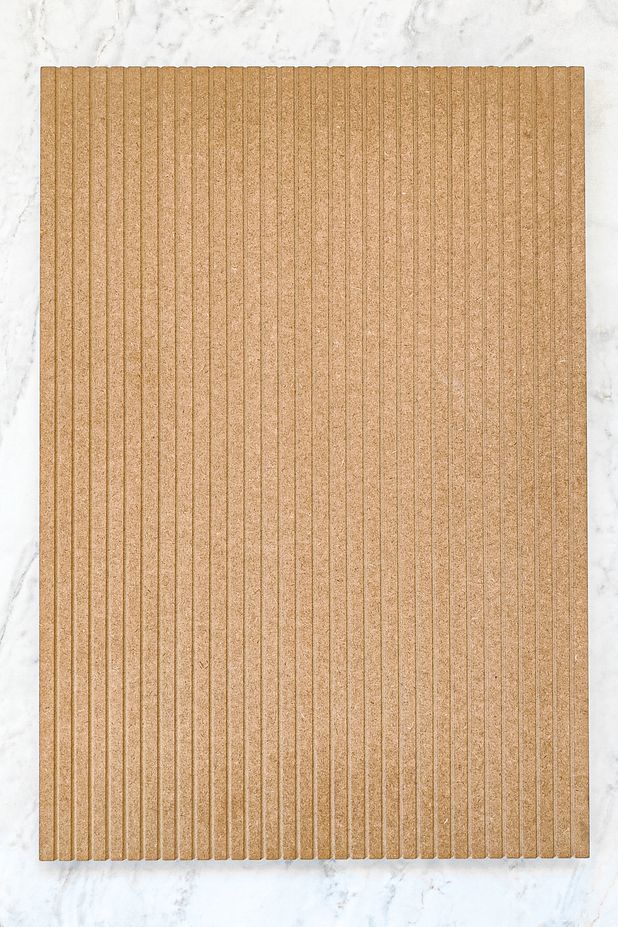

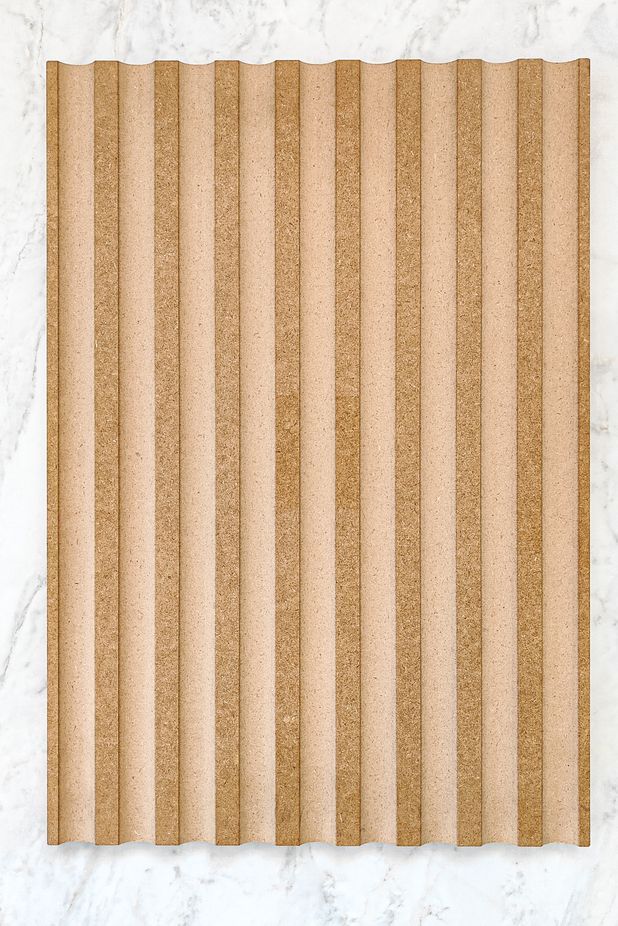

Flutes and waves are some of the latest styles added to the collection, and these reflect the trends for lineal and Art Deco aesthetics that have been seen in design shows across Europe this year.

“The difference between our lineal products and a lot of other lineal products on the market is that cabinet makers or designers can literally design it however they want, and when we're making the doors we actually make the design automatically fit to the panel,” says Lydia. “So they can set up what their maximum spacing will be, and then when we're cutting it we'll fit it to the size of the panel so they won't end up with any big ugly flat bits on the sides.”

Cabinet doors are easily ordered on Sage Doors’ website, and the team at Sage Doors are able to support specifiers to design and specify a bespoke profile.

Another important benefit of Sage Doors’ collection is that it is made from HDF, rather than MDF.

“HDF is a very high density and moisture-resistant substrate compared to MDF, which makes it easier for the cabinet makers and painters to work with. Because the HDF is so much higher density, it is also more durable for long-term use in the kitchen.”

It means rather than creating a two-piece door, which limits the profiles that can be made, doors are created from a single piece of HDF. The material is also ideal for paint-ready doors because it's a lot harder and denser, so it won’t chip as easily before or after it's painted, and it’s the ideal surface for sanding.

“Our sanding system is set up quite differently than other companies, so the cabinet maker should be able to receive the doors and send them straight to their paint shop. We've got different sanding processes that are set up to ensure a consistent, smooth finish.”

Lydia says cabinet makers like the paint-ready finish and the high quality of the doors, and designers enjoy the customisability.

“The amount they can change and adjust profiles to fit their space is what makes the doors so great to use, and the number of lineal profiles that we have means there are just so many different options, which gives specifiers so many opportunities.”

Discover more cabinet door options by Sage Doors