Commercial Roller Doors Auckland: What You Actually Need to Know

Commercial roller doors aren’t just about security. They protect your workflow. And with Auckland’s coastal conditions, high wind zones, and council requirements, getting the specification right from the start is essential.

What Are Commercial Roller Doors?

Auckland business owners often ask us why they should choose roller doors over other garage door types. The answer comes down to practical advantages that matter in commercial settings.

Roller doors suit both residential and commercial properties, though commercial applications demand higher specifications for security, durability, and daily operational demands.

Roller doors are simple, horizontal slats that roll up around a barrel. They take up minimal space because they coil vertically instead of folding back like sectional doors.

Commercial doors are built heavier than residential doors and use thicker steel or aluminium. They're designed for 10-20+ opening cycles per day. And they handle bigger openings - typically 3 to 12 metres wide.

You'll see them everywhere in Auckland. Warehouse loading docks in East Tamaki. Retail security shutters in the CBD. Vehicle workshops in Penrose. Anywhere a business needs security without eating up floor space.

The design keeps things simple: slats, guide rails, a barrel mechanism, and a motor (for automated doors). Fewer moving parts than sectional doors means fewer things to break.

Types of Commercial Roller Doors

Steel Roller Shutters

Steel shutters are for serious security. They're made from galvanised or colour steel in different gauges (thicknesses). Heavier gauge = harder to break through.

If you're storing valuable stock or operating in a high-risk area, steel makes sense. Beyond the obvious security benefits, quality roller shutters can reduce insurance premiums. Many Auckland insurers will drop your premiums when you install proper steel shutters. Sometimes, it's enough to cover the cost difference over a few years.

Steel handles Auckland's weather well. But you need proper powder coating, especially near the coast. Salt air eats through cheap finishes fast.

Finger-safe joins come standard on colour steel sectional doors. The interlocking slats prevent crushing injuries, meeting New Zealand workplace safety standards that imported options don't typically follow.

Insulated Roller Doors

Useful for temperature-controlled environments. Foam-filled slats improve thermal performance, reduce condensation and help stabilise internal temperatures.

If your warehouse is heated, cooled, or stores temperature-sensitive items, insulation provides real operational benefits.

Aluminium Roller Doors

Aluminium gives you strength without the weight of steel. Good for buildings where the structure can't support heavy doors. It also works well when you need manual override capability.

The big advantage in Auckland? Aluminium doesn't rust. If your business is anywhere near the coast, such as Takapuna, Mission Bay, or even just a few kilometres inland, aluminium outlasts steel without the maintenance hassle.

Aluminium dents more easily than steel. So if forklifts are reversing near your door daily, steel might be smarter.

Rapid Roll Doors

If your door opens more than 50 times a day, rapid roll doors pay for themselves.

Standard doors take 30-60 seconds to open. Rapid doors do it in 3-5 seconds. That's a huge difference when you're running a busy loading dock or food distribution centre.

They also reduce energy loss in climate-controlled spaces. Less time open means less cold air escaping.

Perforated and Vision Roller Doors

For retail businesses, you need security overnight, but you don't want to hide your window displays behind solid steel. Perforated doors solve this. They provide security while letting people see through. You still showcase your products after hours.

Vision panels work similarly in warehouses. Fork operators can see what's on the other side before opening, preventing accidents.

Fire Rated Roller Doors

Used in facilities requiring fire separation between areas. These doors are engineered to contain fire for a specified period and must meet the Building Code’s fire safety requirements.

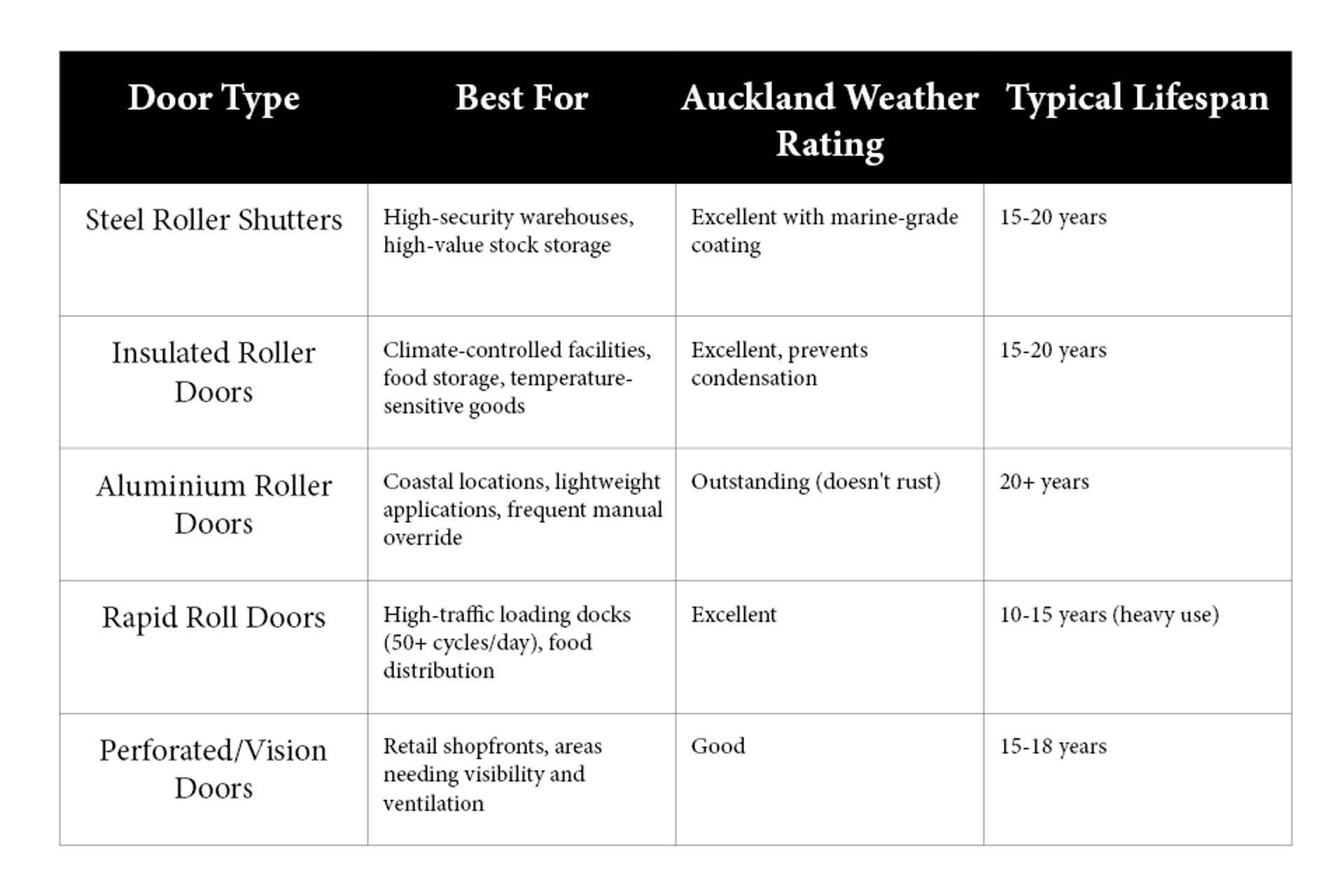

Commercial Roller Door Types: Quick Comparison

Motor Options (Why They Matter)

The motor is one of the most important parts of any commercial roller door system. Choosing the right one means fewer breakdowns, smoother operation and longer service life, especially for businesses opening and closing doors many times a day.

Windsor supplies a range of commercial-grade openers designed for New Zealand conditions and different usage levels. The right motor depends on:

- how many cycles your door does each day

- the weight of the door

- whether you need fast access

- environmental conditions, such as coastal exposure

High-Cycle Commercial Motors

Best for busy warehouses, logistics hubs or manufacturing sites. Built for frequent opening and closing with strong torque, industrial gear systems and advanced safety features.

Standard Commercial Motors

Suitable for moderate daily use such as workshops, small factories and general commercial premises. Reliable performance for sites that don’t require constant door movement.

Light-Commercial Motors

Good for smaller operations, storage units or sites with low daily cycles. These motors are compact and efficient, designed for occasional use without the complexity of heavy-duty systems.

All Windsor commercial motors include:

- safety stop and obstacle detection

- manual override for power outages

- New Zealand electrical compliance

- compatibility with commercial roller door systems

For sites requiring remote access or integration with building systems, smart access controls can also be added.

What Auckland's Coastal Weather Does to Roller Doors

Auckland's environment demands careful material selection. Coastal salt air, high humidity, and wind exposure quickly degrade doors that aren't properly specified for these conditions.

Salt air

If you're within 1km of the coast, standard powder coating won't cut it. You need marine-grade finishes, such as aluminium.

Wind loading

Auckland has different wind zones. Coastal areas and elevated sites face stronger winds. Your door needs an engineering certification for your specific address. We've seen cheap imported doors literally blow apart during storms.

Humidity

Humid weather causes condensation inside buildings, especially warehouses. This is why weather sealing matters. Brush seals and rubber gaskets aren't optional extras. They're essential for keeping water out.

Rain

We get a lot of it. Drainage channels at the base of your door need to stay clear. Clogged drainage = water pooling = rust.

After big storms, check your door. Look for damage, test the operation, and make sure seals are intact. Taking 10 minutes out of your day to check can prevent expensive repairs.

Auckland Council Requirements (The Boring but Critical Stuff)

Many commercial roller door installations in Auckland require building consent, especially when:

- structural supports are affected

- door size or wind loading changes

- the door forms part of an escape route

- fire-rated doors are involved

Consent requirements vary by site, but the council typically wants:

- engineering details

- wind loading documentation

- fire compliance (if applicable)

- installation drawings

- electrical certification for motors

Some simple replacements are exempt, but always confirm before starting work.

Local manufacturers and installers help streamline this process because they understand council expectations and documentation.

How to Choose the Right Door (Without Overthinking It)

Start with these questions:

1. How often will you open it?

- Less than 10 times daily: Standard motor is fine

- 10-30 times: Mid-range motor

- 30+ times: Heavy-duty or rapid roll

2. What are you protecting?

- High-value stock: Steel with proper locking

- Standard goods: Aluminium or steel

- Just weather protection: Lighter gauge is okay

3. Is the building climate-controlled?

- Yes: Insulated door pays for itself

- No: Save the money

4. How close to the coast?

- Within 1km: Aluminium or marine-grade coating

- Further inland: More options available

5. What's your usage environment?

- Food/pharma: Rapid roll for hygiene

- Retail: Perforated for visibility

- Warehouse: Standard roller is fine

Don't over-spec. But definitely don't under-spec on motors or wind ratings. Those mistakes cost you later.

Installation Timeline and What to Expect

- Standard commercial doors: 2-4 weeks from order to installation.

- Custom sizes or complex jobs: Add 1-2 weeks.

Here's the process:

Week 1: Site assessment. Someone measures the opening, checks the structure, and identifies any issues.

Week 1-2: Council consent application (if needed). This runs in parallel with manufacturing.

Week 2-3: Door manufacturing. NZ-made doors are built to your specs.

Week 3-4: Installation. Usually takes 1-2 days for standard commercial doors. Larger or complex jobs take longer.

On the day of installation, expect some noise and disruption. Most installers work around your schedule—early mornings, weekends, whatever minimises impact on your business.

After installation, they test everything. Motor operation, safety features, and weather sealing. They'll train your team on proper operation and emergency procedures.

Maintenance You Shouldn’t Skip

Check your door every three months. At minimum.

What to check:

- Lubricate the moving parts (tracks, barrel, hinges)

- Test the safety reverse—put something in the door's path, and it should stop

- Inspect weather seals for damage

- Look for rust or corrosion (especially near the coast)

- Listen for unusual noises (grinding, squealing)

After storms or heavy rain, do a quick check. Make sure drainage is clear and nothing has been damaged.

Coastal businesses: Check monthly. Salt builds up fast. Rinse the door with fresh water occasionally. Sounds simple, but it adds years to the door's life.

When to call professionals:

- the motor struggles

- the door jumps off the tracks

- springs become noisy or uneven

- the door binds, scrapes, or shakes

- Regular servicing extends the life of the door and protects your business from downtime.

The Local Advantage (Why It Matters)

Local manufacturers understand:

- Auckland’s weather

- coastal corrosion

- high-wind requirements

- council documentation

- common building designs

They can also provide fast service when something goes wrong — essential for commercial operations where downtime is expensive.

Imported doors may look cheaper upfront but often lack local support and fail to meet NZ performance expectations.

Making the Decision

Good modern roller doors for commercial properties last 15-20 years. Choosing the right one ensures:

- compliance with Auckland requirements

- durability in coastal and high-wind zones

- reliable daily operation

- proper safety performance

Most Auckland businesses need:

- steel or aluminium roller doors

- a motor matched to cycle demand

- correct wind rating for their location

- weather seals suited to Auckland’s climate

Get the Right Roller Door for Your Auckland Business

We manufacture commercial roller doors, built for Auckland conditions. Backed by local support, you can actually reach.

Whether you're running a warehouse in East Tamaki or a retail shop in Newmarket, we'll help you find the right door for your needs, not oversell you on features you don't need.

Call us for a free site assessment. We'll measure up, discuss your requirements, and give you a straight quote. No pressure, no corporate jargon, just honest advice from people who've been doing this for years.

Your door matters. Get it right the first time.