SAY HELLO TO THE SL30 - COBALT Electronic Side Load Lock

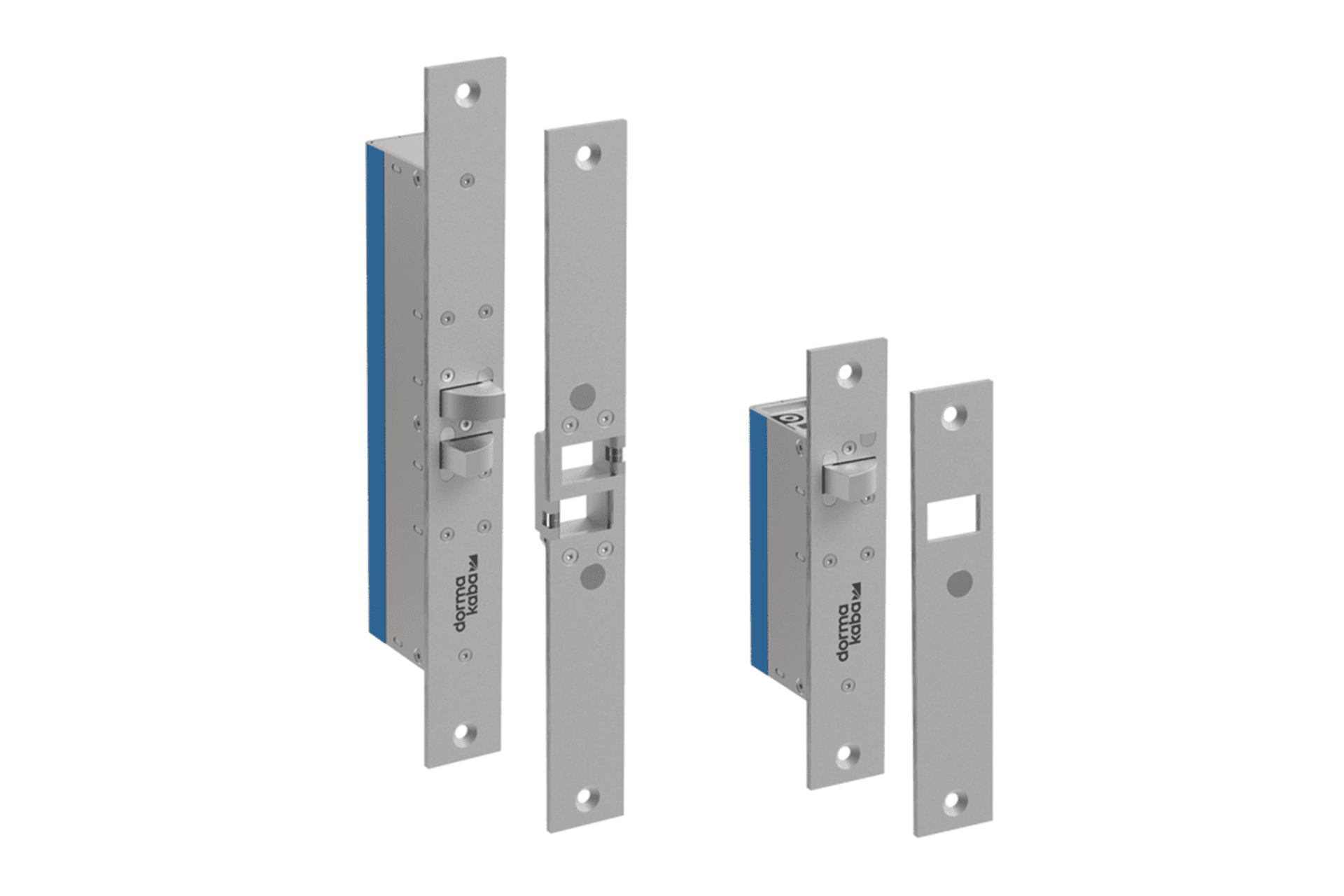

SL30 - COBALT Electronic Side Load Lock effectively addresses the prevalent issue of door misalignment by proactively drawing the door inward, guaranteeing a complete and secure closure. With the capacity to rectify misalignment of up to 8mm, the SL30 - COBALT Electronic Side Load Lock not only delivers top-tier security but also ensures the consistent and secure closure of your doors, leaving no room for compromise.

This cutting-edge technology has redefined the very essence of safeguarding spaces, ushering us into an era of unparalleled security, convenience, and reliability.

Imagine a future where your access control system adapts to your needs seamlessly, where security doesn’t compromise on simplicity and functionality. Where you have total peace of mind, knowing your premises, the people and your assets are safe.

Introducing the SL30 - COBALT Electronic Side Load Lock Series.

Your security, simplified.

BACKGROUND: A high-rise office building needed to revamp their access control and locking on its main entrance. With a constant flow of people coming in and out of the building, the main doors, made of heavy-duty glass, presented an issue as they were often misaligning when closing, causing access control concerns for the building manager.

CHALLENGE: Heavy duty glass doors are prone to misalignment, making it unsuitable for a solenoid lock that would likely malfunction. Paired with the constant high footfall entering the building, the management team required a lock that could operate reliably and robustly in a consistently busy environment. Additionally, to satisfy code requirements, the lock had to release under side-load pressure in case of emergencies.

- SOLUTION: The SL30 - COBALT Electronic Side Load lock offered an ideal solution. One of the only locks on the market designed for 90° swing glass doors, it excelled in reliability with 1 million cycles tested, perfect for high-traffic areas. It safely released under 6000N side-load pressure, providing a safe exit route during emergencies, and also complying with safety regulations.

WHY CHOOSE THE COBALT MOTOR DRIVEN ELECTRONIC LOCK OVER A MAG LOCK?

The Cobalt Series is a low voltage lock, drawing as little as 40mA in standby and only 300mA in operation at 12VDC.

Low current paired with high-security access control makes the Cobalt locks a preferred product choice for eco-conscious industries.

_________________________________________

With user-selectable fail-safe and fail-secure modes, the Cobalt Series is designed to suit all your application requirements.

This offers simplicity when ordering as well as the ability to customize the product failure mode in the event of a power outage.

____________________________________________

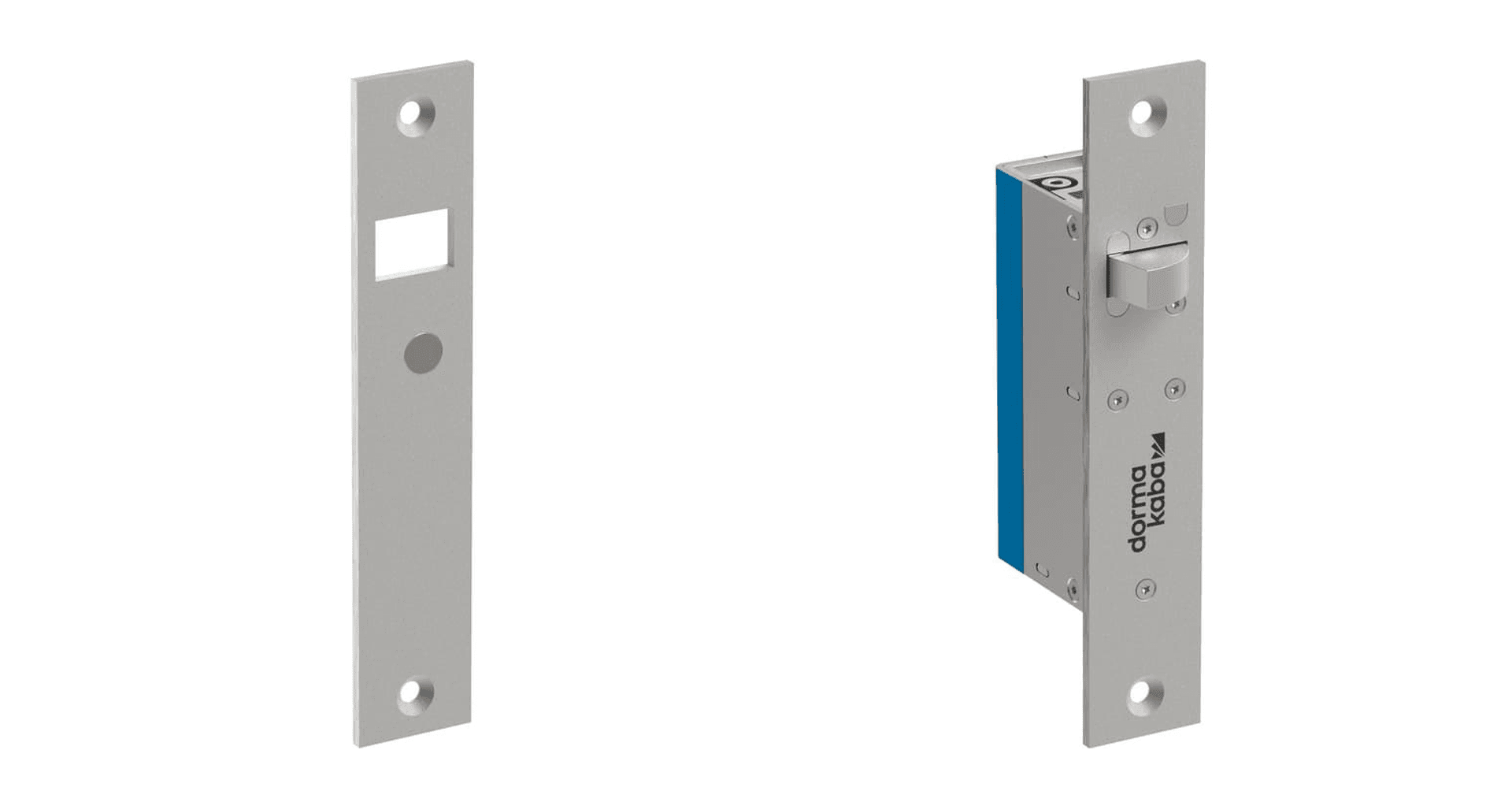

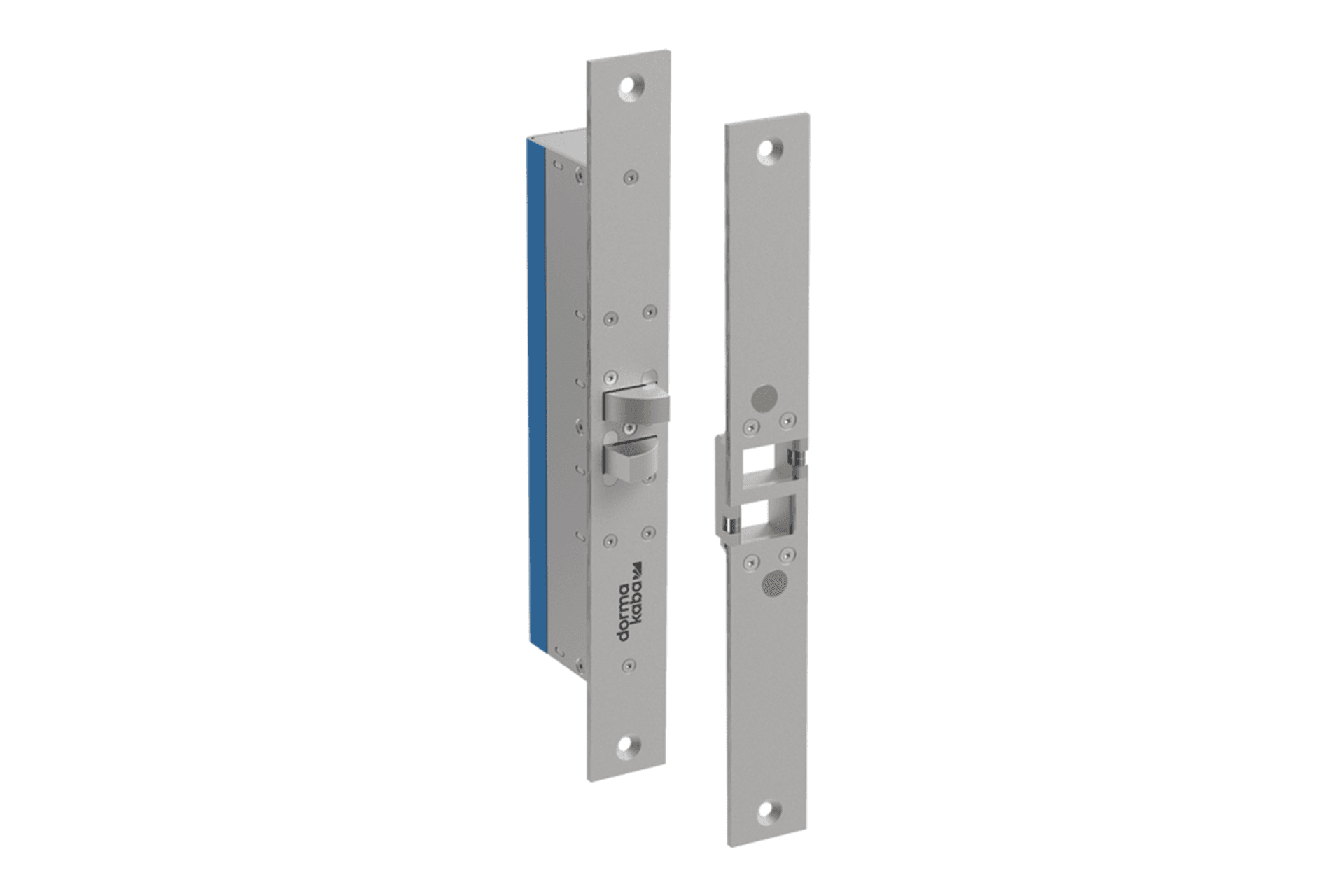

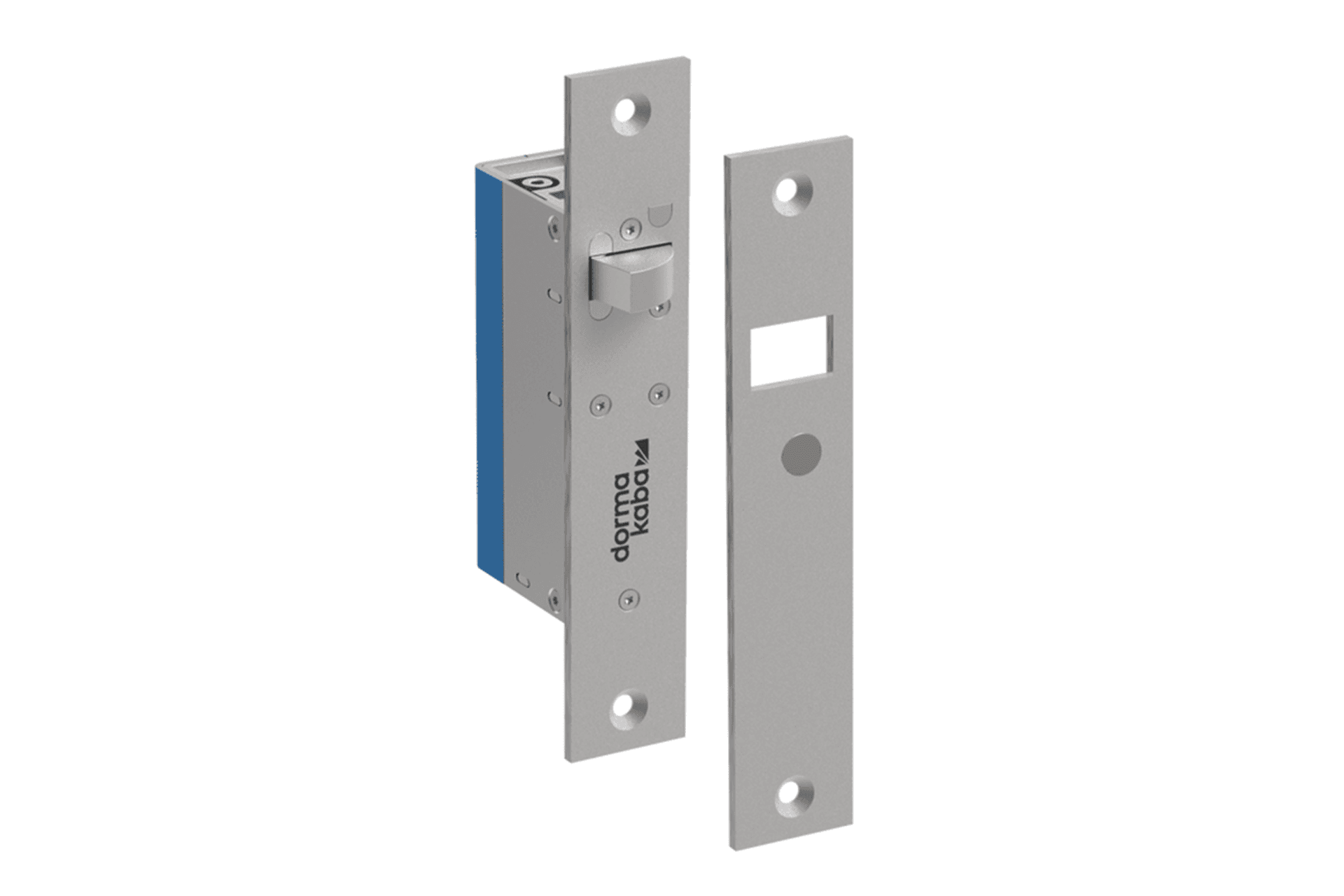

The Cobalt's offer a common installation option:

mortising the lock into the door frame and attaching the strike plate to the door. This preserves head-space, provides a sleek and clean appearance, and eliminates the risk of pedestrian injury associated with maglocks. Alternatively, optional surface mounting of the Cobalt locks still offers a cleaner and safer solution.

___________________________________________

The Cobalt series has a holding force in excess of 10,000N (2250 lbf) and maintains its integrity, security and reliability over the life of the product.

A typical maglock power draw can range between 400 -800mA. 10 to 20 times more than the Cobalt locks.

The Cobalt lock will use up to 95% less power to keep a door locked when compared to a common maglock.

___________________________________________

Traditional maglocks can only operate under a fail-safe model. This means that the lock defaults to an unlocked state when there is a power failure.

-Security Risks

-Vulnerability to Malfunctions

-Limited application usage

-Regulatory Compliance

__________________________________________

A maglock, when installed, protrudes and hangs into the doorway posing a potential safety hazard for pedestrians who may accidentally collide with it. Moreover, from a design standpoint, maglocks are aesthetically unpleasing due to their large cumbersome appearance.

____________________________________________

Conventional Maglocks exhibit a holding force ranging from 2,000N (450lbf) to 5,000N (1125lbf), which typically diminishes over time.

They demand meticulous and often frequent maintenance to sustain optimal functionality and safety, often due to material degradation from environmental factors.