Sustainable New Zealand native veneers

Written by

13 April 2021

•

4 min read

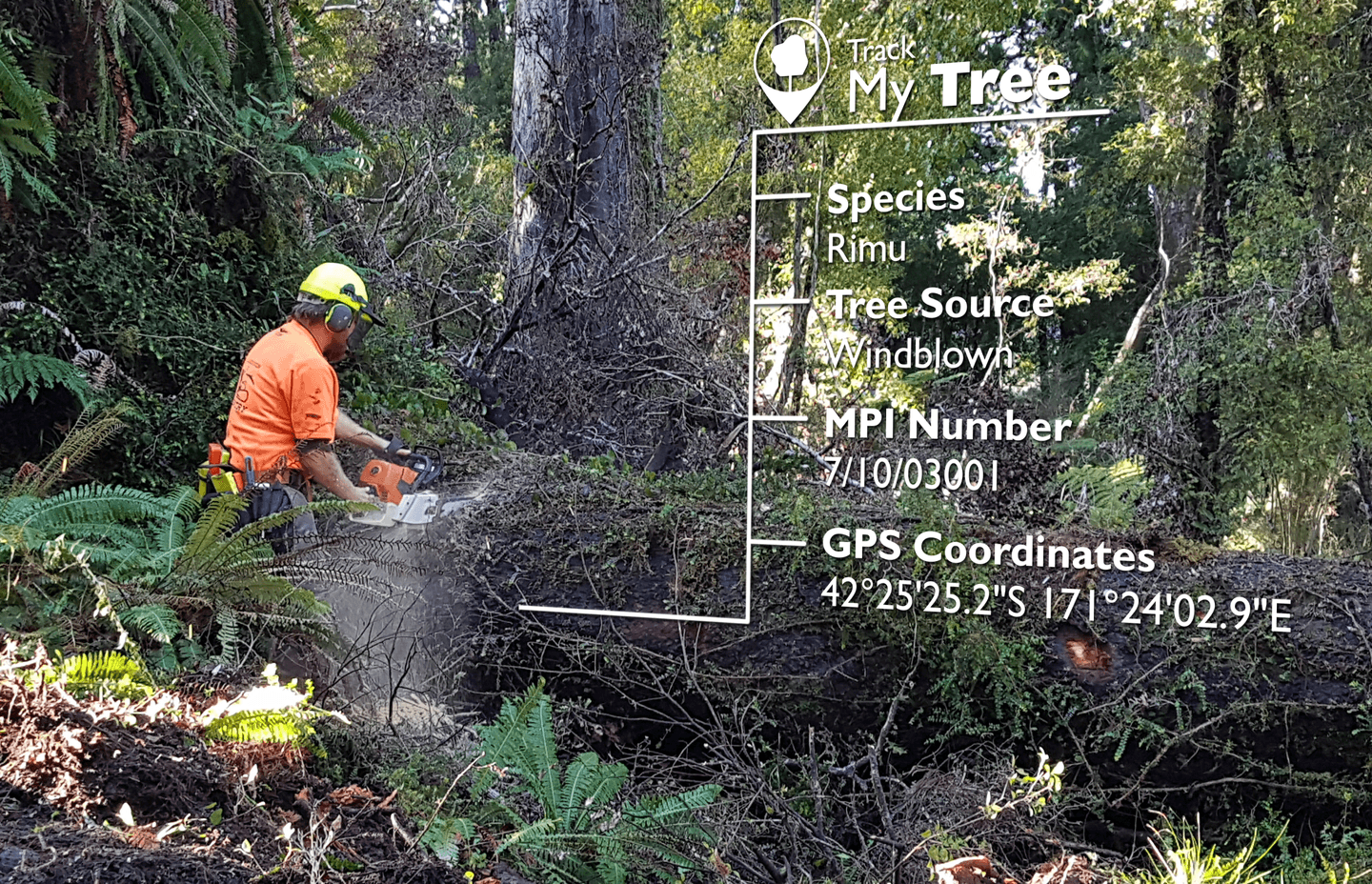

Imagine admiring your new veneer cabinetry and showing your friends a photograph of the tree it was made from—and the exact location from which it came. Not only that, imagine downloading the MPI Permit that goes with it. You would hope said friends would be impressed.

If it sounds to you like it has been done before, you’re right. Icebreaker created the novel concept of the ‘baacode’ for its merino clothing many years ago to track it back to the merino farm where it came from, says Desiree Keown, Group Marketing Manager for New Zealand Panels Group.

“From what we can tell though, this has never been done in the timber industry before and certainly not to this forensic degree of detail.

“The notion of sustainably sourced timber is hardly a new one. There are a number of international accreditations for timber suppliers such as PEFC or FSC, which give assurance that timber carrying those marks has come from verifiably sustainable plantations.

“However, when it comes to native New Zealand timber, the availability of plantation-grown native trees is rare, given their slow growth. The Ministry for Primary Industries has oversight of the local timber industry and issues logging permits for individual native trees, or stands of trees, on private or Maori land—but only where the trees fit into categories such as being windblown, part of an accessway, or salvaged.”

Track my Tree: from forest to veneer

Only millers who are registered with MPI may harvest trees and even then, they must operate under a Sustainable Forest Management Plan or Permit, which includes very strict guidelines for carrying out their logging operations, says Desiree.

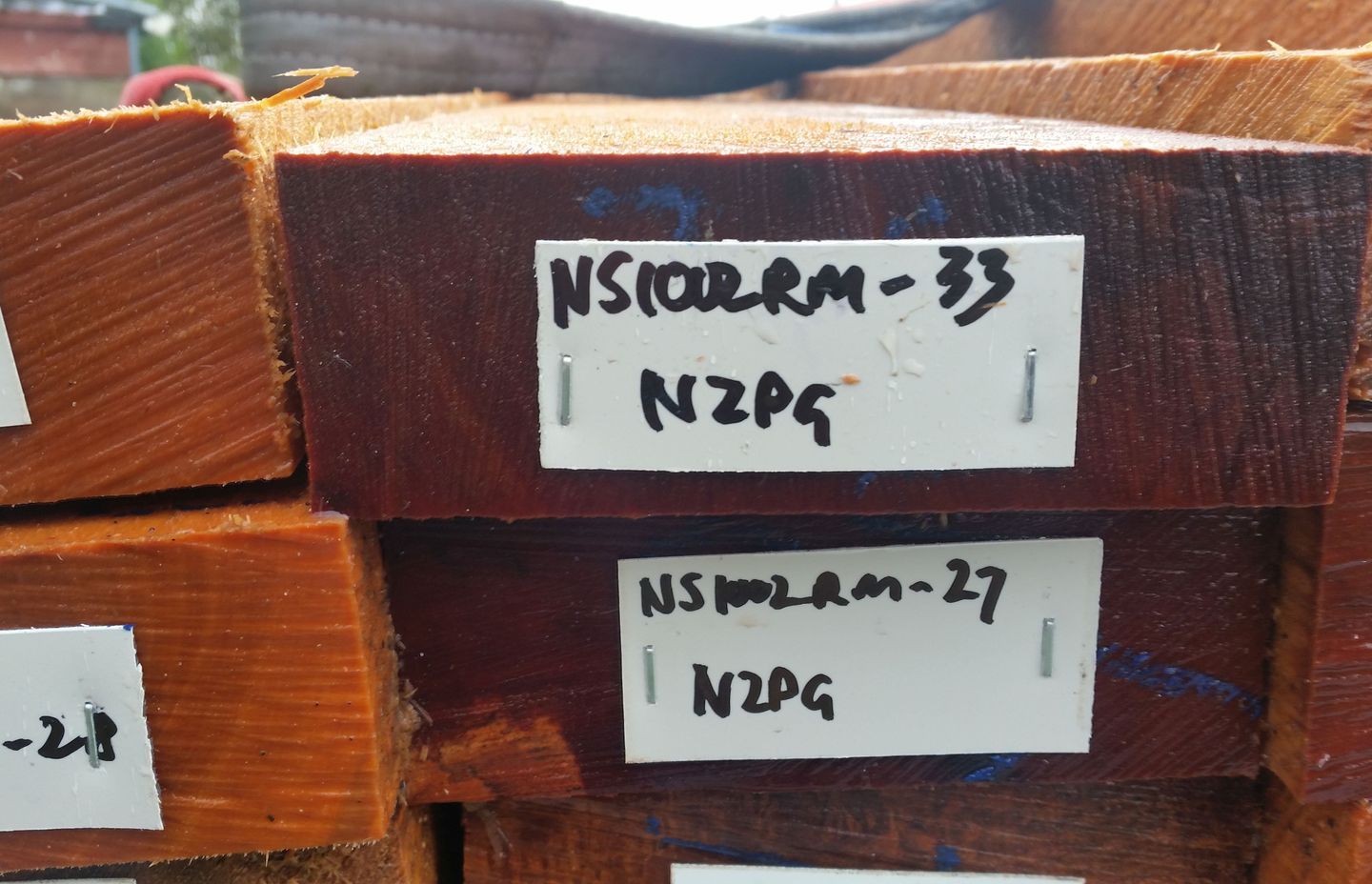

“To make the process transparent from the forest, right through to the veneer press, New Zealand Panels Group took the lead and developed a unique tracking system—Track my Tree—to ensure those precious native trees were clearly identified at the time they were milled. Each unique code travels safely with the tree as it is cut into flitches, sliced and made into veneer layons for pressing at the company’s East Tamaki site.”

Track my Tree was introduced 18 months ago and provides a clear and proven chain of custody from the farm or forest right through to the company’s veneer press. With their own tree guy on the ground on the West Coast of the South Island—and his name really is Guy—New Zealand Panels has been proactively working with local millers to identify native trees and secure a more reliable supply.

Track my Tree: keeping our natives sustainable

Going a step further, the company has made proof of tracking highly visible for everyone to see. Bestwood and Prime Panels are the two product brands owned by New Zealand Panels Group and supply the bulk of native veneer panels to the joinery and construction industry.

“The Track my Tree code is printed on the invoice when the panels are made and sold to a joiner or construction company. The code is also affixed to the side of the veneer panel when it leaves the plant. Entering the code on either the Bestwood or Prime Panels website, returns a search result that shows:

- The relevant MPI permit for sustainable harvest

- A photograph of the tree (or stand of trees it came from). It’s fair to admit that photography is not a primary skill set for saw-millers, so the quality is patchy – but no doubt authentic

- The source type for the tree (or group of trees) such as windblown

- The Google map which shows the area the veneer panel came from

“Even if website visitors haven’t bought our veneer panels and don't have a code, they can still browse the various tracked trees by species.”

With Environmental Choice New Zealand running an annual audit on the company’s products, Track my Tree has been incorporated into this review, providing an added layer of assurance that what they say, is what they do.

Learn more about sustainably sourced veneers.