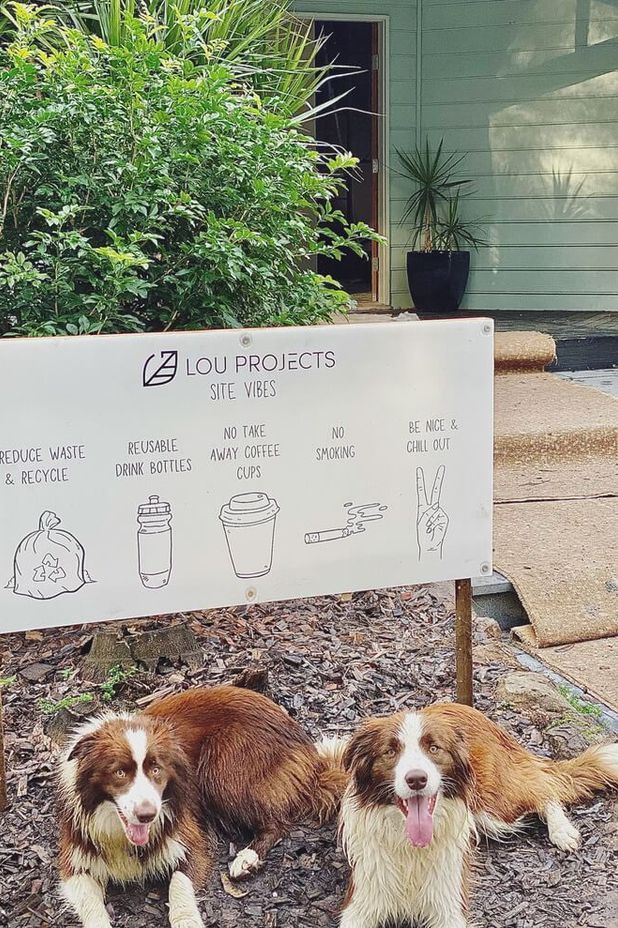

Waste management for a sustainable future

In this article, we dive deeper into how we can better our building practices when it comes to construction and waste management. Building sustainable homes don’t only the design of the house and the choice of materials, but also apply to future proof building practices. At Lou Projects, we teach our team how to manage waste on-site and we always keep an eye out on how to do it better.

WHY WASTE MANAGEMENT IN CONSTRUCTION MATTERS

BUILDING PRACTICES

Sustainable practices in the construction industry are not limited to the materials we choose to use and the building designs we bring to life. Of course, the principles of passive house design and the use of sustainable products that minimise our carbon footprint are integral components of what we do at Lou Projects. However, there is another aspect of our processes that has a significant impact on our ability to offset the environmental damage of construction and demolition. It may not be as glamorous as designing and building beautiful, sustainable homes that sit seamlessly within their natural surroundings, but effective waste management systems are crucial to enhancing our sustainable practices as builders.

THE AUSTRALIAN BUILDING INDUSTRY AND WASTE MANAGEMENT

Did you know that in 2017 alone, the Australian construction industry generated 20.4 million tonnes of waste? Of this, over 6.7 million tonnes ended up in landfills across Australia. These are staggering numbers that point to the dramatic need for the construction industry to rethink how the waste that each project generates can be redirected away from landfills. Currently, in the Australian building industry, there are only limited guidelines imposed on waste management issues. This leaves it largely up to the individual builder to embed positive waste management practices into the culture of their business.

Increasingly in Australia, there are opportunities to recycle and reuse waste from job sites, with local councils providing incentives in the form of free dumping of metal, cardboard and gyprock. If we take advantage of these schemes we will not only be reducing the amount of construction waste that ends up in landfills – we will also be minimising the immense load of carbon emissions derived from the transportation of waste across the country. Despite these initiatives, unfortunately, it is still common practice on many job sites to dump all waste into one giant skip bin, outsourcing waste disposal to an external company that removes the bin from the site once full. There isn’t a great deal of consideration put into the process of sorting waste materials and redirecting them away from landfills. This is one key area that we believe is worth the effort. There are simple, practical and affordable systems that can be established to take care of waste management. There really is no need for materials like cardboard, soft plastics, gyprock, untreated timber and metal to end up in landfills when there are facilities that will accept and recycle them for free.

“It’s about creating a culture in your team and the industry as a whole that we’re all responsible for reducing waste. We all need to be conscious of the small efforts we can make to create the change the industry desperately needs to become more sustainable.”

YOUR IMPACT ON CONSTRUCTION WASTE MANAGEMENT

BUSINESS OWNERS AND RESPONSIBILITIES

As a business owner, it makes sense from the perspective of both sustainability and economics to implement a sound waste management system. Taking the extra time to sort waste could reduce disposal costs from around $400 per tonne to $150 per tonne, which equates to huge cost savings when you consider the lifespan of your company. It really is worth encouraging your team to get on board with a clear waste management plan by opening up dialogue around the many benefits their extra effort can bring.

As Lou Projects owner, Andrew George, says: “It’s about creating a culture in your team and the industry as a whole that we’re all responsible for reducing waste. We all need to be conscious of the small efforts we can make to create the change the industry desperately needs to become more sustainable.”

Andrew is a strong advocate for being assertive when it comes to inspiring others to adopt more sustainable practices in the construction industry. His advice is that suppliers need to know if they are using excessive packaging and that it is up to business owners to refuse plastic packaging for single-use purposes. If we can encourage suppliers to switch to biodegradable packaging or to reduce the amount used for wrapping and transporting their products, then this is one way that we can create greater awareness of waste reduction. If we continue to stand up to suppliers and let them know that we don’t approve of excessive single-use packaging, they will eventually need to change their practices.

EFFECTIVE WASTE MANAGEMENT PLAN

So, what do we believe best practice looks like when it comes to an effective waste management plan? It starts with educating staff and subcontractors to be conscious of the plan, making it clear that it is an important embedded practice that reflects the deeper values of our company. On the worksite, it is about allocating a clearly designated area where different forms of waste can be separated into bays, ready for disposal and recycling. Soft plastics are gathered and taken to a REDcycle outlet, located at our local Coles supermarket so that they can be recycled into a range of different products such as park benches, footpaths and even roads. Metal, cardboard and untreated timber are disposed of separately at designated areas of the local tip, free of charge. It is also possible to make a private arrangement with gyprock suppliers who can provide a disposal service depending on where the job is located. Having worked on many job sites earlier in his career that did not have these simple systems in place, Andrew has seen a dramatic reduction in the amount of waste that is left over once this separation has taken place on his Lou Projects sites.