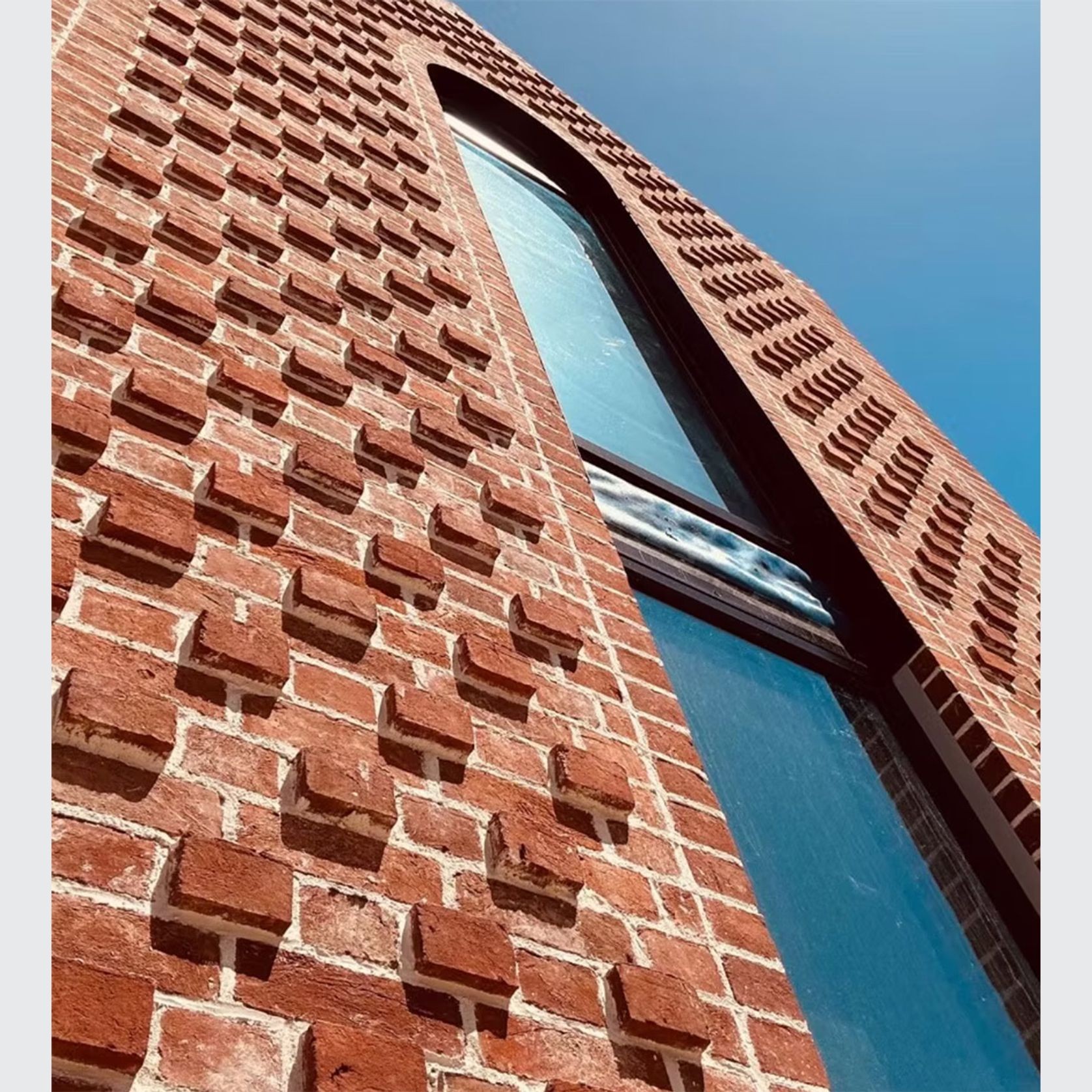

Reclamation Heritage Red Bricks

Elephant Brick Co.- CategoryBricks

- RangeOld Red Bricks

- BrandElephant Brick Co

Other products in this range

About the

Seller

"In a world where conformity often prevails, our dedication to innovation and sustainability stands out. We welcome you to join us on our journey towards a brighter and more innovative future for bricks."

Sustainable Stewardship

We are committed to a greener future. Our brick factory plants more trees each year (fast growing Eucalyptus trees) rehabilitating our clay fields, embodying our belief in giving back to nature. Our bricks works looks more like a forest than a brick works! Furthermore, we harvest our trees for use in paper and pallet production, ensuring we can continue our tree planting while providing a renewable resource to the paper and packaging industry. Our on site solar farm produces 1000kW and we expect to entirely eliminate our use of electricity from non-renewable sources by 2025.

Factory Flexibility

Our factory is built for flexibility, what other brick makers do with 4 separate lines we do with 1. Our clay preparation line supplies clay clots to our hand moulding line, our pressed brick line, our machine waterstruck line and our extruded line. Within 2 hours we can switch between any of these 4 different methods for making bricks.

World Recognised Projects

Our projects have received acclaim worldwide, including the esteemed Wienerberger Brick Award for the Halle St Peters project.

Global Reach

Today bricks produced in our factory are used in 46 countries and counting.

- ArchiPro Member since2024

- LocationView all locations (+4)

- More information