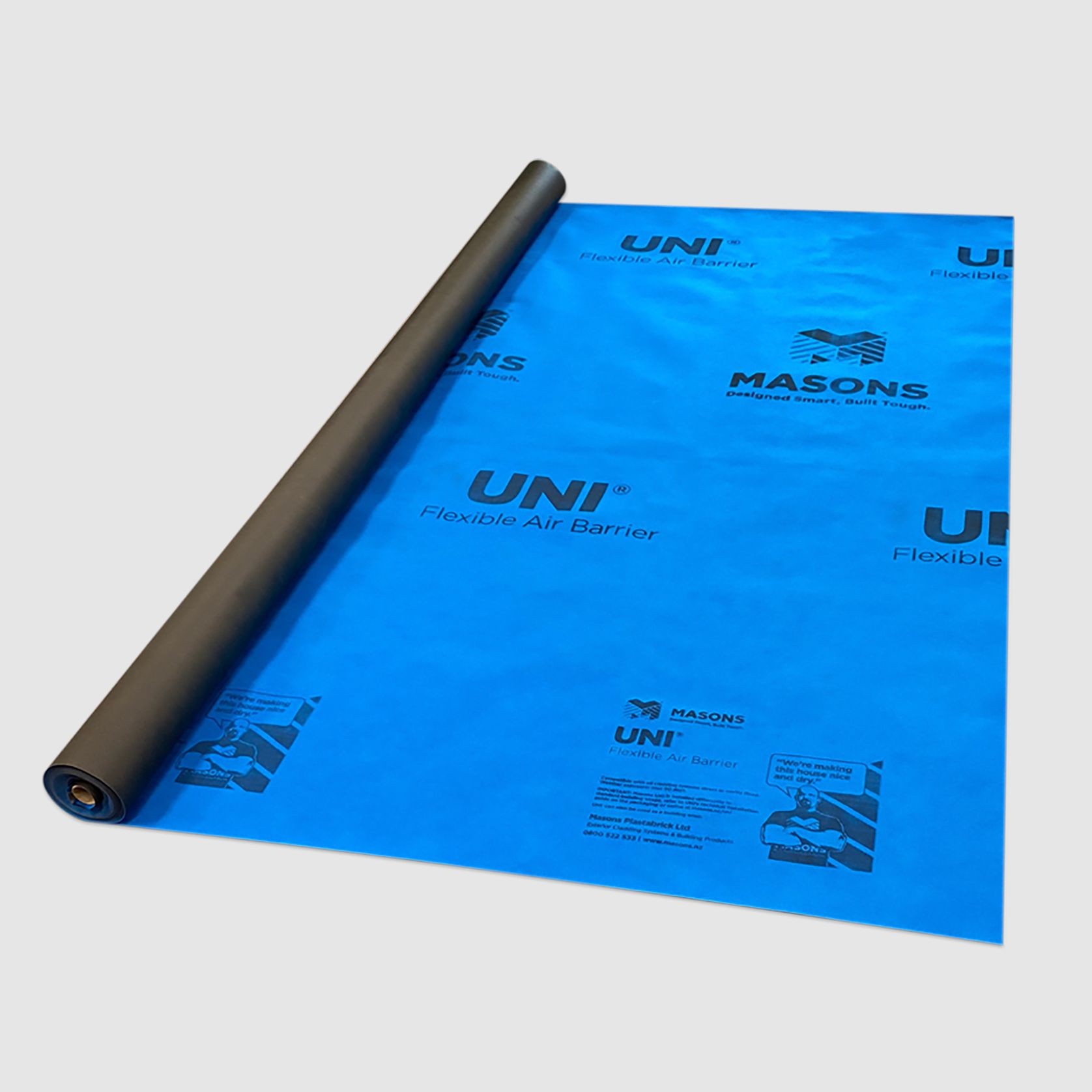

UNI® Flexible Air Barrier

UNI® Flexible Air Barrier is a flexible wall underlay giving early enclosure to builds, allowing work to continue on the inside (for up to 90 days), without waiting for the cladding to be complete.

Once the cladding is in place, UNI® Flexible Air Barrier becomes a secondary line of defence against moisture by ensuring moisture that occasionally penetrates the wall cladding is directed back to the exterior of the building.

Read more below:

How modern air barriers can improve building moisture performance.

A stronger building wrap to keep construction moving.

Your best line of defence against moisture in a high-performance building.

- CategoryPre-cladding

- RangeUNI FLEXIBLE AIR BARRIERS

- BrandMasons Plastabrick Ltd

- Year2019

- Warranty50 years

- UNI® is a nonwoven, absorbent, water-resistant 180 GSM, synthetic wall underlay.

- UNI® is water-resistant and designed to provide temporary protection from weather conditions and UV exposure to timber framing, without the installation of the cladding, which allows for the continuation of internal work on the build for 90 days after installation.

- UNI® comprises three polypropylene layers: two outer layers of non-woven polypropylene with a middle layer of a functional-technical film. It is manufactured to meet the European standard EN 13589-1:2014 as well as the absorbency performance requirement as per NZS 2295:2006.

Location

- In locations with a wind design pressure (ULS) of up to and including 4.6 kPa (which includes all NZS 3604:2011 wind zones).

- In seismic zones up to and including seismic zone 3.

- In all exposure zones.

- Further than 1 m from a relevant boundary.

Building

- For commercial and residential construction.

- Designed for use with all cladding systems.

- Performs on timber and steel framed buildings.

- As a temporary cladding for up to 90 days.

- With buildings of all building heights, up to the permissible wind design pressure of 4.6 kPa.

- With cladding and joinery that complies with the relevant provisions of the NZ Building Code for the site and location.

- Suitable for use as a non-rigid backing for stucco plaster.

- UNI® is suitable as an air barrier on walls that are not lined.

- For vertical use only, not suitable as a roof underlay.

- UNI® must be covered with a suitable wall lining to any occupied spacings.

LIMITATIONS

- UNI® (or any flexible air barrier) cannot provide seismic (bracing or racking), and fire-resistance.

- For lightweight steel, a thermal wrap must be installed.

- Where a building height is greater than 10 m and upper levels contain sleeping uses or other property the external wall must be subject to specific fire engineering.

- In occupied spaces, UNI must always be installed in conjunction with an internal lining.

- UNI® must be covered within 90 days from installation.

NEW ZEALAND BUILDING CODE STANDARD (NZBC)

- UNI® meets or exceeds the requirements of the NZBC.

- Product Assurance Supplier Statement; PASS. Documentation is available from the downloads button on this page.

If designed, installed and maintained in accordance with all Masons Plastabrick’s requirements, the UNI® will comply with or contribute to compliance with the following performance claims:

B1 STRUCTURE: B1.3.1, B1.3.2, B1.3.3 (a, e, f, h, j, m, q, & UV), B1.3.4 (a, b, c, d, e)

- Manufactured to EN 13859-2:2014; tested to EN 12311.2:2013 for tensile properties, EN 12310.1:2010 for resistance to tearing, EN 1107.2:2002 for dimensional stability based on supplier’s technical data and testing specification [Masons Plastabrick, 30/08/2021b].

B2 DURABILITY: B2.3.1 (a), B2.3.2 (b)

- Manufactured to EN 13859-2:2014; tested to EN 1297 & EN 1296 for UV exposure and UV exposed samples tested to EN 12311.2:2013 for tensile properties, EN 12310.1:2010 for resistance to tearing, EN 1924.2002 for resistance to water penetration based on supplier’s technical data and testing specification [Masons Plastabrick, 30/08/2021b].

2 FIRE AFFECTING AREAS BEYOND THE FIRE SOURCE: C3.4 (c)

- Manufactured to EN 13859-2:2014; tested to EN ISO 11925-2/ AC:2011 for reaction to fire based on supplier’s technical data and testing specification [Masons Plastabrick, 30/08/2021b].

E2 EXTERNAL MOISTURE: E2.3.2, E2.3.5, E2.3.7 (a, b, c)

- Manufactured to EN 13859-2:2014; tested to EN 1928:2002 for resistance to water penetration, EN ISO 12572:2004 for water vapour transmission properties, EN 12114 for air resistance based on supplier’s technical data and testing specification [Masons Plastabrick, 30/08/2021b].

- Tested to AS/NZS 4201: Part 6 for absorbency [Scion, 02/2020].

- Installation details and requirements meet E2/AS1, E2/AS4.

F2 HAZARDOUS BUILDING MATERIALS: F2.3.1

- Manufactured to EN 13859-2:2014; the product does not emit harmful materials based on supplier’s technical data and testing specification and material safety information [Masons Plastabrick, 30/08/2021a, 30/08/2021b].

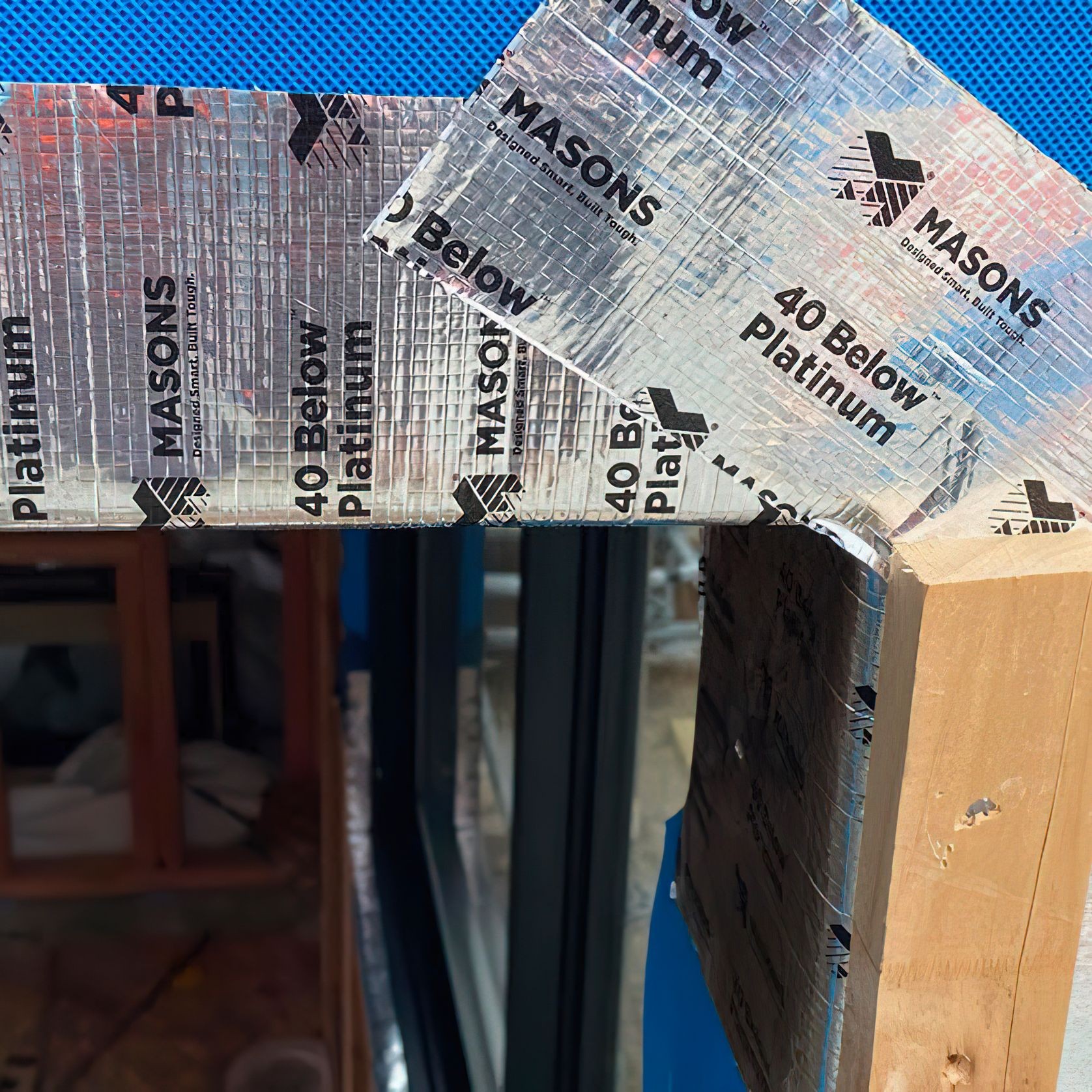

Masons UNI® is to be installed with the correct components:

- Masons 40 Below flashing tapes (ensuring weather-tightness around windows and joinery),

- Masons UNI Fasteners or UNI Cap Nails (to an engineer specified fixing pattern which ensures wind-loading up to ‘Extra High’)

- Masons Penetration Seals

- Masons UNI FAB Seam Tape

- Masons Corner Guards

- Masons PEF Backing Rod

- Masons BrickTies

Collectively these products complete the weather-tightness of the building membrane.

General Installation Instructions:

- Fix with the printed side out

- Run the wrap horizontally

- Pull taut over the framing before fixing

- Only to be fixed with Masons UNI Fasteners either with a gun or hammer. Staples must not be used.

- For timber frames: use 32mm Nail/washer. For steel frames: use UNI washers with either a Phillips or square drive self-drilling screw.

- Be lapped, not less than 75mm at horizontal joints; Have upper sheets lapped over lower sheets to ensure that direction of laps will allow water to be shed to outside of the wall underlay

- Be lapped, not less than 150mm over studs at vertical joints

- Extend 50mm below bottom plate or bearer

UNI Flexible Air Barrier must be installed by a Licensed Building Practitioner using Mason's full installation instructions.

These instructions are available as a video or a printed version in the downloads button of this page.

Training on-site can also be arranged via your Masons Rep.

Masons UNI®, whether on or off-site should:

- Be stored on end under a cover, in a clean and dry area

- Protect the rolls from crushing or damage

- When fixing the product in windy conditions, care must be taken due to the large sail area created by wide roll widths

- Eliminates expensive delays due to hold-ups on cladding or bad weather

- Once installed, UNI® works as a secondary line of defence against moisture over the life of the building, whilst still being highly breathable, passing vapour from the inside of the building out.

- A fraction of the cost of rigid air barriers (materials and labour) whilst having most of the benefits

- Much thicker and stronger than standard building paper/wrap

- Quick and easy installation

- Codemark Certified

More from

Masons

About the

Seller

Masons provide a range of quality trade building products from a complete Enclosure Building Wrap System and Exterior Cladding, to Brick Reinforcement, and are a crucial supplier in the New Zealand building industry.

Masons strive to be at the forefront of developing innovative products that raise the standards of New Zealand building products.

- ArchiPro Member since2020

- LocationView address

- More information