Ditch the ‘duck and cover’ for full access

Written by

24 July 2021

•

4 min read

Anyone who has renovated or built a home will know that sinking feeling when the weather sets in and their home isn’t at watertight stage. The anxiety around the potential level of damage, not to mention time lost waiting for the weather to clear, is palpable. There are also flow-on effects for contractors who are also impacted.

Back in the day, you would erect a patchwork of tarps and hope that they would do the job of keeping most of the water out, and while they did do a pretty passable job, there were other shortcomings, says Mark Scheib, Director of All Safe Scaffolding.

“The biggest issue for builders using tarps was the need to ‘duck and cover’ around and under them, which becomes quite an arduous process, as well as throwing up a whole raft of health and safety concerns.

“Tarps are also not 100 per cent effective, especially when strong winds are added to the climatic conditions, resulting often in work being called off in bad weather anyway, leading to delays in the schedule.

“Luckily, a solution exists that resolves all of these issues—shrink wrapping.”

Shrink wrapping: protecting your most valuable asset

“Shrink wrapping is a much better proposition both in terms of safety and in expediting the job by allowing for a full, productive day’s work to be undertaken without bad weather impeding progress.

“There is also no need for set up and pack down on a daily basis, meaning once the project’s quantity surveyor has set the schedule, all parties are assured that that is the timeframe to work towards.”

Mark says that with such assurance in place, the time savings can result in around 20 per cent faster completion of a job—something of benefit to all parties.

“The upfront cost varies depending on the size and height of the project as well as property access but with the timeframe assurances involved, shrink wrapping becomes a cost-effective option, particularly on bigger projects.”

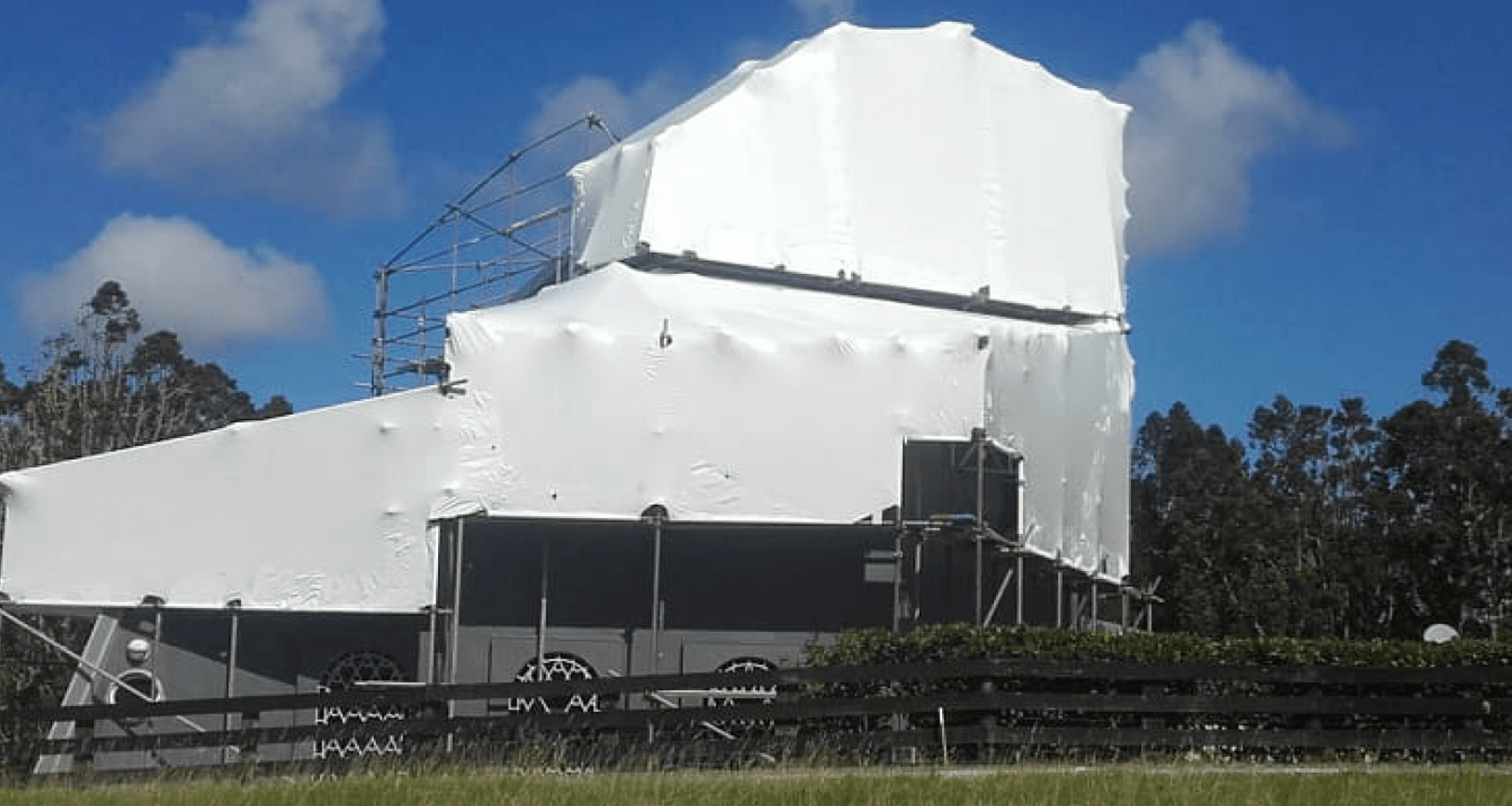

The shrink wrapping process starts with the erection of scaffolding around the project and to a height of two metres above the roofline, which allows contractors to work comfortably unimpeded by weather. The shrink wrap is composed of a virgin resin product—similar to black polythene—that shrinks up to 30 per cent when heated and becomes ‘springy’.

Mark says it takes around 2–3 weeks to set up the scaffold and carry out the shrink wrapping and at the end of the project the wrap is collected and sent to a recycling facility where it is pelletised and used in the manufacture of plastic pipes for the construction industry.

All Safe Scaffolding: experts in scaffolding solutions

All Safe Scaffolding has more than 12 years’ experience in shrink wrapping and has been offering the shrink-wrap service as a matter of course for around 10 years.

“We’ve been involved in some pretty big re-clad jobs around Auckland and shrink-wrapping is pretty much the industry standard on large-scale residential projects; with smaller projects you might risk going with the tarp system but we always price and quote jobs with this product as a matter of course.”

Mark says All Safe Scaffolding also does scaffolding-only projects both commercial and residential and generally works on projects from Omaha to Pukekohe.

“We work with the client from pre-construction through to when we install the system, especially on a renovation project where a new roof can often require a new pitch. Working with the engineer’s report, which will set out the loading requirements, we can design the right system for each project.

“Our decade-plus experience means our clients can be assured that we have got the structure vs strength ratio right and can design a system capable of working with winds of up to 100km/h. I’m proud to say that in all that time we have never suffered any real ‘blow outs’—testament to the All Safe team’s expertise.

Mark also says that customers can rest assured that while the majority of the product comes from the US—some is manufactured in New Zealand—supply has not been affected by COVID-19.

Learn more about the benefits of shrink wrapping your next new build or renovation project.