Unlocking the new finishes and applications of New Zealand bluestone

Written by

01 October 2024

•

5 min read

Breaking new ground with technology

Quarrier and supplier, Timaru Bluestone continues to transform an age-old craft with cutting-edge technology. The stone mason’s new polishing machine, purpose-built in Turkey, is now at the core of the New Zealand-based company that specialises in working with locally sourced bluestone.

The local manufacturer’s innovative machine allows the masons to achieve a range of new finishes for New Zealand specifiers. “We can do all the previous finishes on the stone, but now we can do sandblasting and bush hammering through the same machine,” says Renè Kempf, Managing Director of Timaru Bluestone.

“For example, we might do a bush hammer and then a brush over it,” Kempf adds.

The machine performs multiple processes that once required several machines, thereby streamlining production and providing more creative possibilities for specifiers.

Improving efficiency and sustainability

Aside from the artistic advantages, the polishing machine's efficiency is a standout feature. “The previous machine operated 40-50 hours a week,” Kempf explains. “The new machine runs only 20 per cent of the time because it's more efficient.” This leap in productivity means that the company can meet increasing demand with fewer resources, highlighting its commitment to environmental sustainability.

However, this focus on sustainability extends beyond the machine. “We’re not importing stone from overseas; our bluestone comes from our own quarry in New Zealand. The majority of basalt products sold in New Zealand come from Asia," says Kempf.

However, Kempf remarks only a fraction of the stone from its quarry makes the cut for high-end projects. “We only use about 10 per cent of what comes out of the quarry, which is selected for its quality – some rocks are suitable for tiles while others are more suited to landscape or streetscape projects,” says Kempf. The rest is used for purposes like protecting riverbanks and ports, ensuring no organic material goes to waste.

Celebrating nature’s variations with bluestone

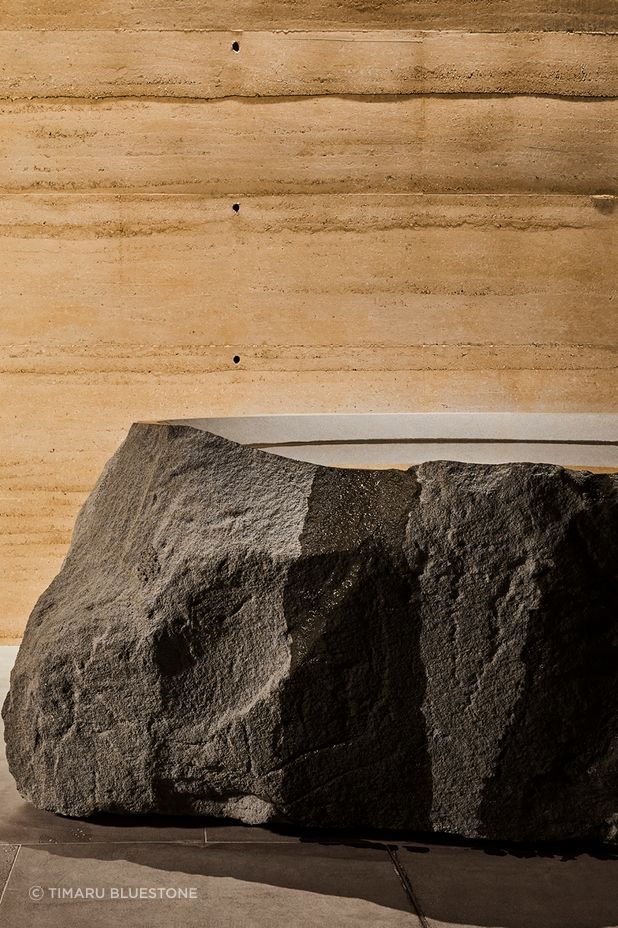

Timaru bluestone is a basalt formed from volcanic lava that offers natural advantages for specifiers and homeowners on various commercial or lifestyle projects. It is ideal for internal and external applications because it has a naturally non-slip surface. According to Kempf, it's often used in civic projects where safety is critical, as well as house cladding, pool coping, bathroom tiles, and coffee tables.

The aesthetic appeal of bluestone is undeniable, "Our stone tends to advertise itself. People call up, asking if it's our bluestone coffee table in the Britomart hotel. And yes, it is," Kempf remarks. The distinctiveness of Timaru Bluestone products, from large bespoke pieces like fire hearths to small furniture items, adds to its growing reputation.

One of the unique aspects of the Timaru Bluestone’s basalt is its natural variation in colour and texture, which is derived from the volcanic origins of the stone. “Part of the beauty of our stone is the variation in colours, from blue, grey to warmer tones,” says Kempf.

Timaru Bluestone’s project highlights

Timaru Bluestone’s bespoke projects are noteworthy additions to the design world, from private homes to public terminals.

- Queenstown House is surrounded by a rustic landscape complemented by the abundance of bluestone throughout the interior and exterior of the design. The masons at Timaru Bluestone carefully selected each beautiful, one-of-a-kind stone, creating this unique property.

- Auckland Experience Centre, by Fisher & Paykel, is the result of a design collaboration featuring incredible sculptural elements and natural materials representing Ngāti Whātua Ōrākei ancestral narratives, as well as luxury kitchens designed with Arclinea, Boffi and Henrybuilt. Supported by an adze-finished timber plinth crafted from 45,000-year-old swamp kauri sits a section of bluestone – this ‘hot rock’ contains an induction element used to brew kawakawa tea, a native plant with healing properties. In addition to the 'hot rock', a freestanding bluestone water feature adds to the overall ambience of the experience centre.

- One of the company’s most notable projects was a collaboration with Christchurch International Airport. The airport boasts a 125-metre-long wall of Timaru Bluestone running behind the check-in counters. The bluestone was subtly etched to represent the Waimakariri River, for which Canterbury is known for.

With innovation driving its craft, this company is poised to continue pushing the boundaries of stonework, offering a blend of efficiency, sustainability, and artistry. "In New Zealand, what we're doing with bluestone is unique," Kempf proudly states, and it's clear that Timaru Bluestone’s unique approach makes them a standout in the industry.

View more projects by Timaru Bluestone or contact them on ArchiPro today.