Mosman Apartment Retrofit - Mosman, NSW 2088

By Australian Glass Group

In Mosman, New South Wales, windows in this 1960s apartment block were in need of an urgent upgrade. The original timber window frames were in a terrible condition with considerable wear and tear, rot damage, air leaks, and peeling paint. The single glazing also gave no reliable protection from the sun and had near-zero insulation.

Challenges presented themselves in all key areas of its current Glazing:

SOLAR CONTROL

Passive heat can lead to unwelcome heat entering a building on hot days. In the apartment building, the current glass let in 88 per cent of direct sun heat causing uncomfortable temperatures for occupants during summer. To try to keep cool, occupants would draw curtains and run cooling systems for long durations.

In addition, during long hot summer days, the brickwork, roof tiles, footpaths and roads absorb heat and re-radiate it outward at night time – that heat then enters the building through the glass and causes round the clock heat gain issues in summer.

GLARE AND FADING FACTORS

Being 3mm single glazed regular clear glass, there was little protection against the strong glare affects from sunlight as well as fading factors from harmful UV rays. Blinds where often closed due to this.

INSULATION

The 3mm glass in rotting timber with obvious cracks and gaps, provided virtually no Insulation during colder times of the year.

INTERNAL CONDENSATION

Dew point is where temperature and humidity meet and condensation forms. With such current glazing it was common to see internal condensation on the glass that would eventually pool along the timber framing, adding to the mould and rotting affect of the aged timber.

ACOUSTICS

Just like the impact on Insulation, such glass and rotting timber allowed noise to enter inside very easily.

Retrofitting both the glass and frames to energy efficient Insulglass LowE Prime<sup>®</sup> Double Glazing inside Kinzel Industries’ uPVC frames, brought the building into the future of Energy Efficiency as well as immediately impacted the comfort, wellbeing and health of the tenants living inside.

SOLAR CONTROL

The change to Insulglass LowE Prime<sup>®</sup> resulted in nearly half of the direct sun heat being blocked from entering through the glass. The special silver based metal coating in the softcoat low-E also stopped the majority of re-radiated heat from entering inside at night on those long hot summer days – providing a more comfortable temperature level during the day and night.

Occupants now do not have to leave blinds closed all day long and demands on the cooling systems were reduced, providing a healthier living environment. According to one tenant, “The internal temperature has been reduced and is more moderate now.”

GLARE AND FADING FACTORS

The neutral tone of Insulglass LowE Prime<sup>®</sup> provided glare protection against the intense northern Sydney sun, lowering the original Visible Light Transmittance (VLT) of 90 per cent down to a more suitable 70 per cent without looking too dark or noticeable as a full tinted glass. A tenant confirmed that, “Glare…has been reduced significantly.”

Occupants now receive comfortable levels of sunshine and the advanced metal based coating also provides increased protection against harmful ultraviolet (UV) rays which can fade internal wooden flooring, carpets, furniture, artwork and paint colours.

INSULATION

As a high performing solution, the performance of Insulglass LowE Prime<sup>®</sup> exceeded expectations with a dramatic 72 per cent improvement in insulation. This allows for any heat produced inside to be retained more on those cold days and nights as well as keeping the cold from outside entering in – resulting in a significantly lower demand for heating, “Conservatively 20-30 per cent,” noted a tenant.

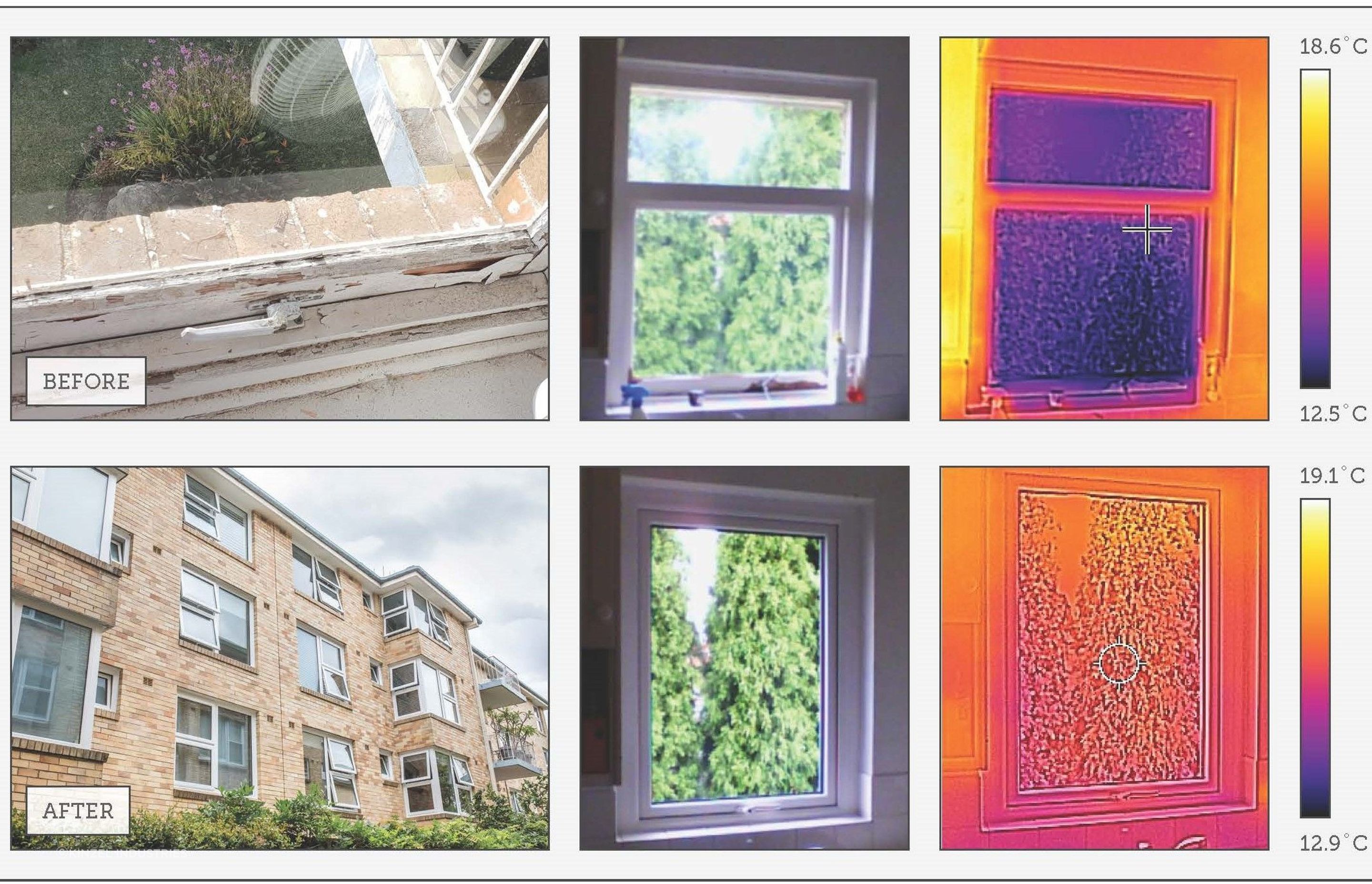

This effect can also be physically seen in thermal images, highlighting the before and after effects on a cold day. The double glazed softcoat low-E insulation also works on hot summer days by increasing the effectiveness of air conditioning – working similarly to a Thermos, keeping a hot drink hot (when it’s cold outside) and a cold drink cold (when it’s hot outside).

All of this results in significantly less demand for heating and supports less demand in cooling on hot days. Less energy waste and less energy costs – all year round!

BEFORE

Greater heat transfer from inside to out through glazing and frame as shown by the thermal imaging. Glass and frame are colder than the surrounds as indicated by purple colouring.

AFTER

Heat is retained, closing the thermal wound in the wall. The silver coating of the softcoat low-E glass reflects heat back into the room. This results in increased glass temperature as indicated by the orange colours of the thermal image.

Professionals used in

Mosman Apartment Retrofit - Mosman, NSW 2088

More projects from

Australian Glass Group

About the

Professional

We are one of the markets’ leading glass processors offering high performance glass products made right here in Australia from one of our three local processing plants: NSW, VIC and TAS.

Our Vision

To be the Service and Product differentiated market leader in double glazed units across South East Australia.

Our Values

- Go home Safe every day

- Do it Right first time, every time

- Put the Customer at the centre of everything we do

- Recruit, train, respect, inspire and develop our People every day

- Take Ownership in everything we do

- One Business, One Team

Our Value Proposition

- Service Excellence

- Product Leadership

- Make it Easy to do Business with AGG

We are your glass experts and can help with solutions to meet your needs as well as satisfy NCC requirements with certified compliance.

We believe in beautiful sustainable buildings and support Australia’s internal and external Climate Change goals. We do this through our passion and sharing of our knowledge and experience to guarantee the best possible outcome of higher quality glazing in the use of our buildings that are Energy Efficient.

We specialise in high performing LowE Double Glazing and boast a wide range of options available to suit your needs. Detailed glazing specification reports are available for your project as well as full engineered design and sign-off solutions.

- ArchiPro Member since2024

- Follow

- More information