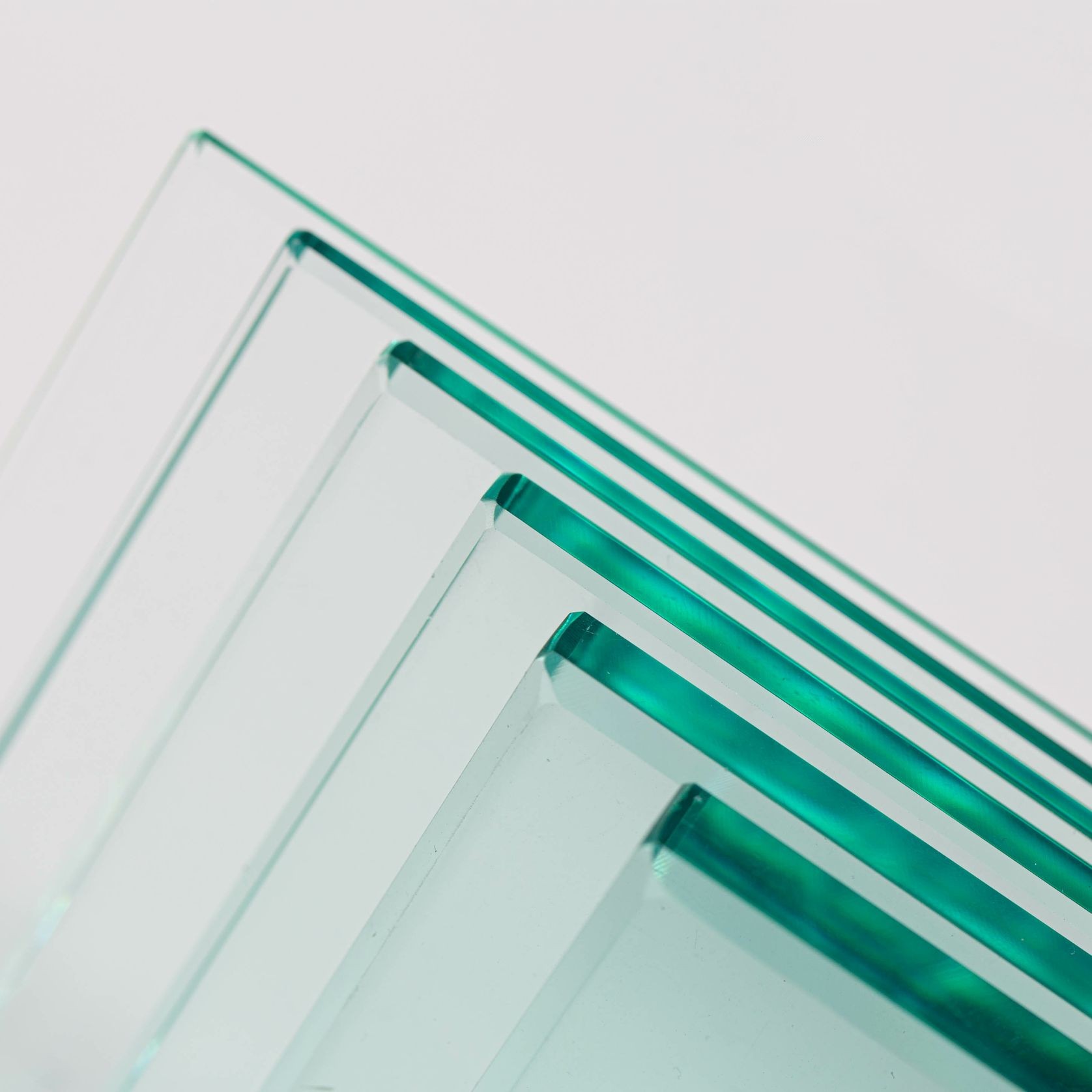

Float Glass

Metro Performance Glass- CategoryGlazing, Shower Boxes

Projects featuring Float Glass

More from Metro Performance Glass

About the

Seller

Discover the best glass solutions for your construction projects with Metro Performance Glass.

New Zealand’s largest glass processor with manufacturing sites located in Auckland, Wellington and Christchurch, supported by 12 distribution centres throughout the country.

Producing a diverse range of customised glass products that are used in both residential and commercial construction. Our range of products includes Low E double and triple glazing, solar control glass, frameless glass showers and balustrades, mirrors, splash backs, canopies, doors and internal partitions.

The right glass can enhance the beauty and comfort of any living space. Our high-tech glass range can transform rooms by creating stunning new features that will add a touch of elegance and sophistication to every part of your house.

- ArchiPro Member since2015

- LocationView all locations (+12)

- More information