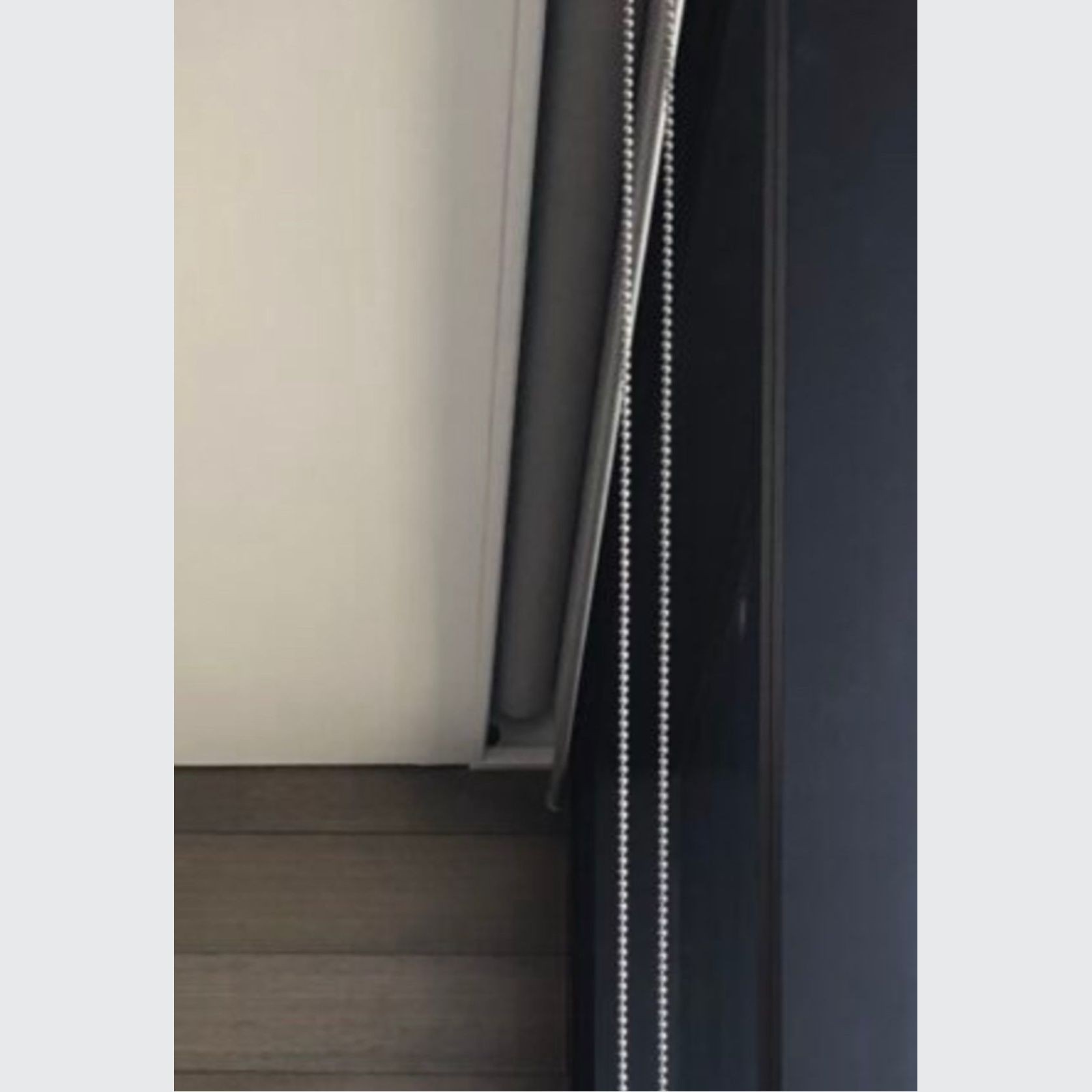

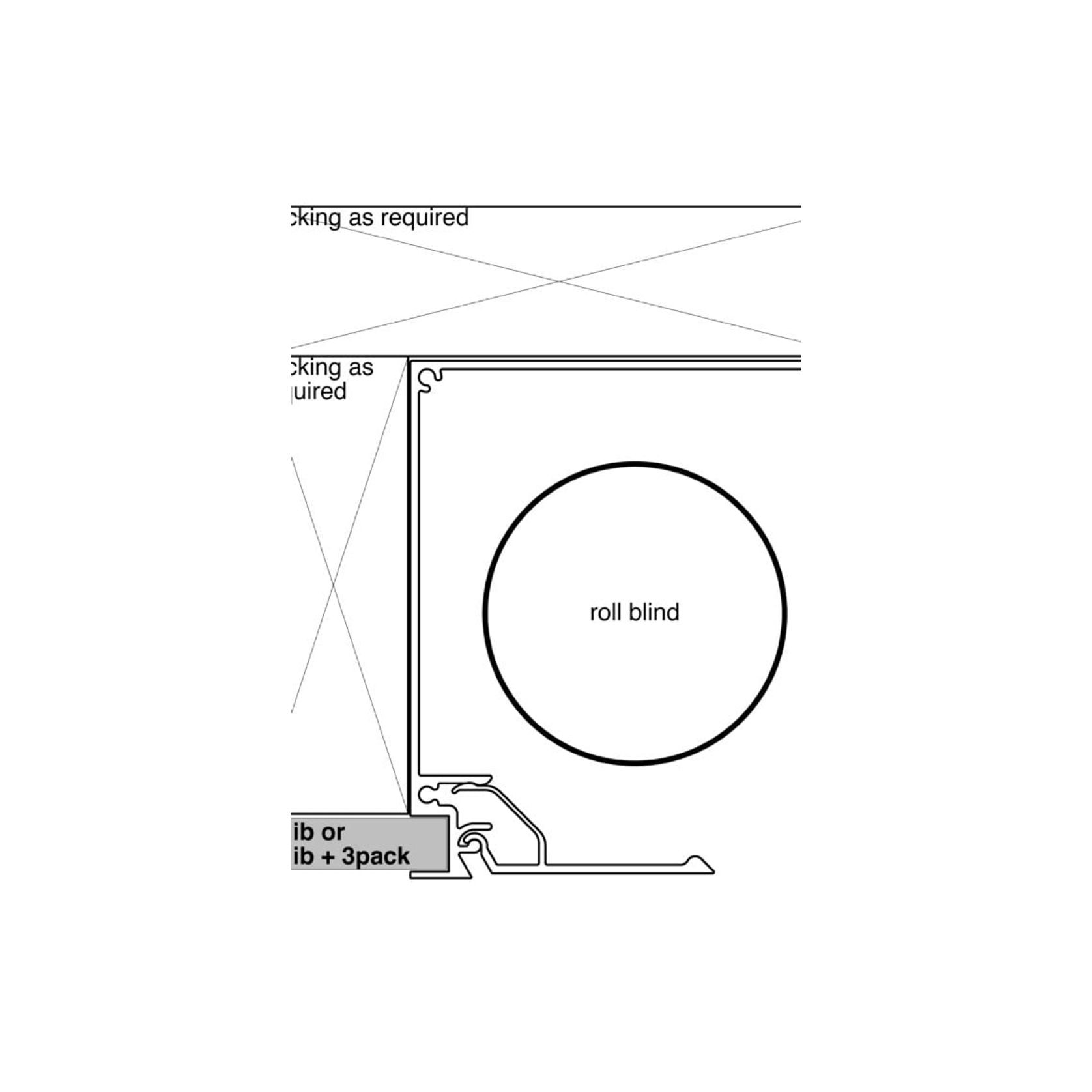

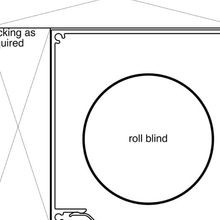

HB1220 Recessed Blind Box for Motorised Roller Blinds

Halliday + Baillie- CategoryRoller Blinds

- RangeBlind + Drawer Extrusion

- BrandHalliday + Baillie

- DesignerHalliday + Baillie

- Fitting typeIntegrated

- Country of originNew Zealand

- Package typeSpecial shipping required

- Care and cleaningEasy maintenance

- InstallationProfessional installation required

- AssemblyProfessional assembly required

About the

Seller

Halliday + Baillie architectural hardware products not only look good – they feel good and will stand the test of time.

Handles may be turned or touched a thousand times a day, so aesthetics, materials and finishes have been a top priority right from the origins of the company.

Our range includes sliding & pivot door hardware (including a full range of flush pulls, end pulls, pull handles, flush bolts, locking and privacy sets), stair rail brackets, door stops, drawer and blind extrusions and wet area vents.

Halliday + Baillie has been in business for 30 years, and manufacturing and exporting hardware worldwide for well over 25 years. The Halliday + Baillie range of products are proudly produced in New Zealand & Australia where lower volumes enable careful monitoring with a correspondingly high production quality.

Along with our own products, Halliday + Baillie are also the exclusive suppliers in New Zealand and Australia for both the famous German FSB range of architectural door hardware and stocking the first, and original TECTUS concealed hinges by Simonswerk.

We expanded H+B into Australia in 2003 with main hub in Sydney and more recently a display studio in Melbourne. We have suppliers around Australia who help Halliday + Baillie designs be available throughout Australia.

Email us for more on: sales@hallidayandbaillie.com

- ArchiPro Member since2021

- LocationView all locations (+1)

- More information