About

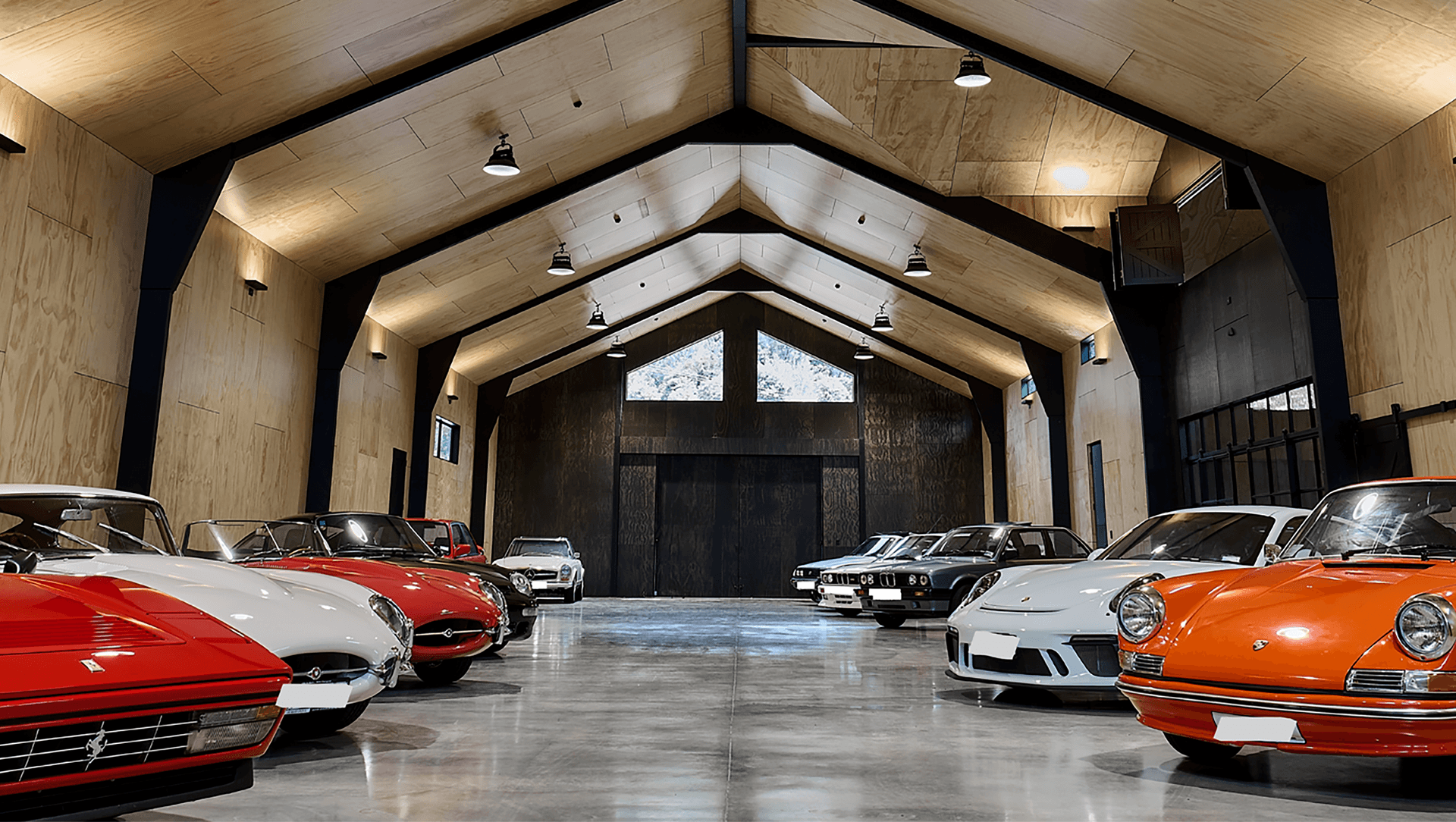

PlyPlay Car Display Shed.

ArchiPro Project Summary - A sophisticated car shed featuring PlyPlay, designed to showcase vintage cars while providing comfortable living accommodations, combining durability and aesthetic appeal with a high-quality finish.

- Title:

- Creating a sophisticated car shed with PlyPlay

- Manufacturers and Supplier:

- Bates Surfaces

- Category:

- Residential/

- Renovations and Extensions

Project Gallery

Views and Engagement

Professionals used

Bates Surfaces. Bates Surfaces has been a leader in surface-coating building products since 1953, utilising the best UV-coatings technology in the world.

As New Zealand’s largest applicator of UV coatings, we have been a trusted supply partner to the local industry for over 25 years.

We transform products, such as raw fibre cement panels, into pre-finished, factory-coated products – working with manufacturers as they make them part of their product catalogue.

In addition to fulfilling OSM orders for customers such as James Hardie and Laminex, we market our own brands – PureCoat™ kitchen and bathroom panels, PlyPlay™ pre-finished plywood wall and ceiling panels, and hygienic Fenta™ Ceiling Tiles.

Founded

1953

Established presence in the industry.

Projects Listed

24

A portfolio of work to explore.

Responds within

1d

Typically replies within the stated time.

Bates Surfaces.

Profile

Projects

Contact

Project Portfolio

Other People also viewed

Why ArchiPro?

No more endless searching -

Everything you need, all in one place.Real projects, real experts -

Work with vetted architects, designers, and suppliers.Designed for Australia -

Projects, products, and professionals that meet local standards.From inspiration to reality -

Find your style and connect with the experts behind it.Start your Project

Start you project with a free account to unlock features designed to help you simplify your building project.

Learn MoreBecome a Pro

Showcase your business on ArchiPro and join industry leading brands showcasing their products and expertise.

Learn More