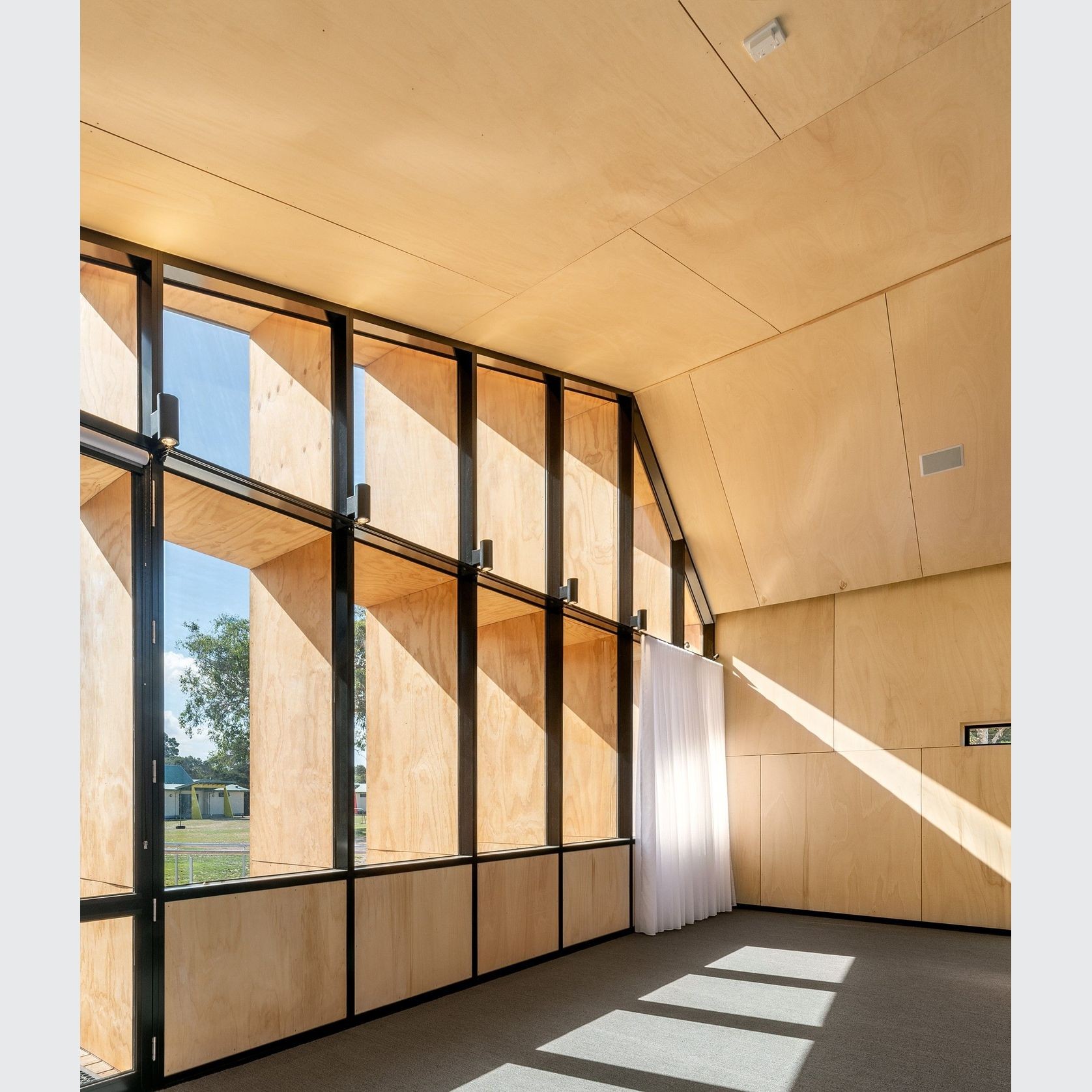

DesignerPly Powder Coated

ForestOne- CategoryWall Panels & Cladding , Suspended Ceiling, Timber

Projects featuring DesignerPly Powder Coated

More from ForestOne

About the

Seller

We are an Australian-owned company focused on delivering quality locally manufactured and sourced, wood-based and decorative building products that enable architects and designers to Specify Responsibly.

Since our inception under the Gunnersen brand more than 140 years ago, we've been a major player in the building industry, providing excellent service, and supplying materials for building and interior design. We're immensely proud of our history and now even more excited about our future direction, enabling architects and designers to build a sustainable future. Our mission is to source and supply best-in-class materials that empower specifiers to achieve their sustainability goals.

If you're a project specifier, work with us and experience the difference that comes with a century of know-how, a global supply network and a progressive drive for innovation.

- ArchiPro Member since2021

- LocationView all locations (+9)

- More information